Automatic Self-Cleaning Filter Delivers Solution for Difficult-to-Treat Industrial Waters

From oil and gas production to desalination projects, multiple industries are driving demand for high-efficiency solutions to the problem of suspended solids removal. Automatic self-cleaning filters have been around for decades but haven't been able to meet increasingly rigorous conditions in "difficult-to-treat waters." Designed specifically to solve these issues, the Spiral Water® Automatic Self Cleaning Filter has demonstrated the advanced performance that today's industries require.

Most automatic self-cleaning filters cannot handle high-solids loading, nor oil and grease, making them insufficient for many industrial applications. Organizations have to rely on traditional solutions such as bags, cartridges and media filters, resulting in equipment redundancy, large footprints, expensive human resources, and an unfavorable environmental impact.

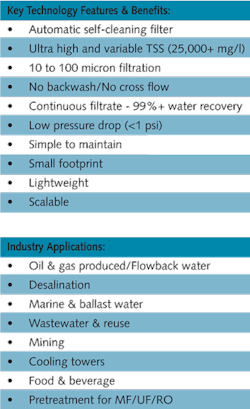

U.S.-based Spiral Water Technologies, Inc., however, has developed the next generation automatic self-cleaning filter technology specifically to address the challenges of difficult-to-treat waters. The company's patented Automatic Self-Cleaning Filter consists of a rugged stainless steel filter screen and a spiral-shaped brush that continuously cleans the screen without any backflush, crossflow or downtime.

Whereas other automatic filters are cleaned once every few minutes, the Spiral Water filter is cleaned up to 600 times per minute. Solids are driven to the bottom of the filter housing and stored in the debris collection chamber until they are expelled through a purge valve. Influent concentrations of suspended solids can be variable and as high as 25,000 mg/L, and filtration ratings are available from 10 to 100 microns. The technology is low maintenance, modular and scalable.

"Customers have reported they've tried 12 to 15 other automatic filters with no success," said Dave Peterson, Spiral Water business develoment manager. "Spiral Water has survived where others have failed to handle the high-solids loading, including oil and grease presence."

The gains have often been exponential compared to competitive products. The Spiral Water filter is capable of filtering up to 100 times dirtier water while using only 10 percent of the energy and a fraction of the footprint. Further, it provides finer filtration, lower CapEx, lower OpEx, and 99.9-percent water recovery.

For more information, contact [email protected].