Ozone = Freshness and Safety for Foods

We live in a culture that relies on technology to “enhance” and protect our quality of life. We see it in personal care products, pharmaceuticals and cosmetics, transportation options to rapidly move around our community and the world, and in water softeners and under-sink reverse osmosis water treatment systems to enhance municipally treated water that’s already a safe, reliable product.

Earth-Friendly Bactericide

Bacteria, yeasts and molds are everywhere in nature - and we can be assured will get on our food in some way. Some may be there naturally. The bacteria on food products can be pathogenic or spoilage type. Pathogenic organisms can make you sick but won’t necessarily have a negative effect on product appearance; while spoilage organisms will make the taste, texture, color or smell unappealing, but may not make you ill as not all are necessarily bad for your health.

Bacteria grow rapidly from 40-140°F, with some doubling in number every 20 minutes. Historically, humans noticed game would maintain a fresh appearance longer and cause less illness when stored in a cool cave. Later, humans harvested ice for cold storage and, in the late 19th century, invented mechanical refrigeration (compressor with refrigerant). It’s only since 1996 that governments have mandated use of HFC 134a, a more earth-friendly refrigerant in place of Freon®, a serious upper atmosphere ozone depleting chemical.

A Tool for Food & Water

Most readers already know ozone (O3) is a very reactive form of oxygen proven excellent in oxidation and disinfection of water and wastewater. The multiple benefits ozone delivers in water and wastewater have been harnessed for many industrial processes over the years - and now include food processing.

Ozone is used to disinfect food products - as well as process water used to prepare them - ranging from “whole” foods to “fresh cut” produce and pre-packaged ready-to-eat products and meat, poultry and fish products.

A non-specific anti-microbial agent, it will kill a large percentage of organisms present in water or on food and processing surfaces that it contacts. This includes both pathogens and spoilers! The benefit from a properly designed and operated ozone system is a reduction in total and target organisms resulting in safer and fresher food products with no change in appearance and with no adverse impact on the user or environment.

This benefit is now realized at food processing plants, grocery store produce misting systems and in your kitchen. Yes, there are small ozone systems for home use. The key to successful application of ozone in food processing is knowledge of the ozone dose, residual and decay process for a specific food product and process where ozone is to be used. This requires on-site testing or working with manufacturers and system providers who’ve invested in the research necessary to provide systems that will work.

Reducing Spoilage

Freshness is measured by our senses and each person will have a different perception, the negative result being something that cost money is thrown in the garbage. Many ozone professionals, either alone or in combination with potential customers, have invested time and money to determine design parameters to achieve desired results - based on these perceptions.

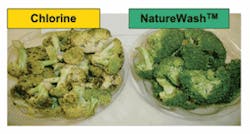

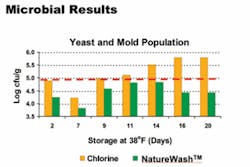

Figure 1, from Praxair, shows cut broccoli florets rinsed with chlorinated water at typical residual levels and with water containing ozone residual after 58 days of storage at 38°F. Research on yeast and mold populations shown in Chart 1 indicates the reason for reduced spoilage of the ozone rinsed product.

Strickland Produce of Nashville, TN, invested in an ozone system in 2002. It was recirculating highly chlorinated water from a 7,000 gallon chilled water tank to rinse fresh cut lettuce, cabbage and carrots prior to ready-to-eat packaging. It found it necessary to dump the tank several times per day as the organic and biological load increased, resulting in high energy use for chilling fresh water to the system and high water and sewerage charges.

Now, Strickland uses a 1.5 mg/L ozone dose to its 200-gpm recirculating flume flow rate and low chlorine residual to package a product viewed by retailers and consumers as superior in quality. And it dumps the 7,000 gallon tank just once a day.

Similar research by BOC Food Safety Group indicated ozone provided enhanced inactivation rates on hard-to-kill foodborne pathogens like Escherichia coli and Listeria monocytogenes that can thrive at cold temperatures, and if present, would multiply in the refrigerator and could cause illness.

Many food processors are adding ozone treatment to their “multiple intervention” approach to food safety as is currently the direction in the municipal and bottled water industries, which incorporate ozone in their “multi-barrier” approach to protection of public health.

Feed Gas Needs

Ozone used in food processing is typically applied to food products or processing surfaces in solution, although low concentration ozone gas is used in grain, nut, citrus and potato cold storage facilities. As in all ozone applications, ozone is made from air or oxygen. There are specific feed gas quality requirements that must be met for reliable operation. Next, the ozone generator converts a percentage of the feed gas (1-12%) to ozone. This ozone gas stream is mixed with water for aqueous use or with recirculating air for contact with food products and surfaces.

Ozone Safety

Workers or end users must not be exposed to ambient ozone levels above those regulated by OSHA or the EPA. OSHA ozone safety exposure limits in air entail:

• 0.1 ppm by volume - 8 hour time weighted average

• 0.3 ppm by volume - 15 minute ceiling

• Human Sensitivity - 0.01-0.05 ppm by volume

Unused ozone gas lost from the treatment process must be converted back to oxygen. And, equipment construction materials should be compatible for long term exposure to ozone.

Summary

It’s ironic that ozone, our Earth’s protective layer, depleted by discharged refrigeration chemicals, is now being purposely produced and used in conjunction with refrigeration to improve both food safety and enhance freshness. Payback on investment can justify the addition of ozone treatment systems. IWW

About the Author: Paul Overbeck is director of the International Ozone Association-Pan American Group. A full day technical session on “Ozone in Industrial Applications” including an Ag-Food Processing Forum, is planned during the IOA-PAG annual conference Sept. 17-20 in Arlington, TX. Contact: [email protected] or www.io3a.org.

Ozone Food Regulatory Status• US FDA - Nov. 5, 1982 - Final rule published - O3 declared GRAS for treatment of bottled water. [21 CFR §184.1563].• USDA/AMS - December 2000 - Ozone is listed in the National Organic Program Final Rule (Subsection 205.605 (b) (20) - Nonagricultural (non-organic) substances allowed as ingredients in or on processed products labeled as “organic” or “made with organic (specified ingredients or food group(s)).”• US FDA - June 26, 2001 - Final rule published - “The FDA amends food additive regulations to provide for the safe use of ozone in gaseous and aqueous phase as an antimicrobial agent on food, including meat and poultry.” [21CFR §173.368].• USDA/FSIS - December 2001 - “The use of ozone on meat and poultry products, including treatment of ready-to-eat meat and poultry products just prior to packaging, is acceptable,” and that there are “no labeling issues in regard to treated product.”