Instrumentation guide for produced water applications

Hydraulic fracturing has emphasized the need to clean up water produced from oil and gas wells, and proper measurement is vital for this effort.

By Steven Smith

Produced water refers to any water brought up to the surface during oil and gas production, typically as the result of drilling, exploration and hydraulic fracturing. Before disposing of or reusing the water, it must be treated to extract hydrocarbons and satisfy environmental code regulations. Being precise and efficient in water treatment is becoming more and more prominent in these applications. Achieving the required levels of control and monitoring requires instrumentation and analyzers to measure composition, flow, level, pressure and temperature.

Cleaning produced water typically costs 300 times more than cleaning municipal wastewater and 3,000 times more than cleaning irrigation water. A new well will produce a relatively small percentage of water; however, as the well ages the ratios change. At the end of a well's life, as much as 98% of the recovered liquids could be water.

Produced Water Treatment

Produced water is a general term, and since each system can vary based on the water quality and the environmental regulations for its reuse, there is no universal treatment process. Nevertheless, basic requirements must be met when dealing with produced water. It is important for companies to understand these factors so that oil and gas production can be maximized while containing costs and complying with regulations.

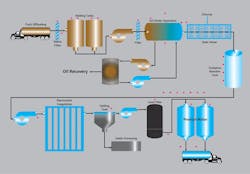

A typical water treatment process performs these functions:

- Removes petroleum hydrocarbons, oil, grease and solids

- Removes friction reducers and other polymer additives

- Removes inorganic scale forming compounds

- Kills bacteria

- Removes iron (Fe)

- Removes total dissolved solids (TDS)

Multiple parameters may need to be monitored in the final water:

- Iron

- pH

- Free Chlorine

- Turbidity

- ORP

- Conductivity

- Temperature

After treatment, the water can be injected into a surface well, pumped into the sea, an aquifer or a river, used for agriculture or industrial process water, or reused for hydraulic fracturing.

Instrumentation Requirements

Flow, level, pressure, temperature and analytical measurements are made at various stages of the treatment process.

In the holding tanks for incoming water, instrumentation measures tank levels, flow into and out of the tanks, and the differential pressure (DP) across the debris filter to detect clogging. Because oil and water separate in the tank by gravity, radar level sensors are often used to detect the level and the interface between water and oil. Conductivity instruments are also used. They are able to see the difference between the low conductivity of oil and the high conductivity of water, and send conductivity levels to the automation system controlling the oil/water separator so it can adjust the separation process accordingly.

Capacitive level sensors, mounted above the water dump valve on holding tanks and separation vessels, can detect the change from water to oil. Signals from the capacitive sensors tell the control system that it can safely pump oil-free water from the bottom of the tank (called "water dumping"). When the sensor detects oil, meaning that the water has been evacuated, it sends a signal to stop pumping, thus preventing oil from being sent to the water treatment process.

Before and in the oil/water separator, instrumentation measures the DP across the filter, conductivity, and level. Level measurements here are typically done with a radar level sensor.

Analytical instrumentation plays a bigger role in the chlorine static mixer and the oxidation reaction tank. In this section, analyzers measure pH, oxidation reduction potential (ORP), free chlorine and conductivity.

No analytical instrumentation is used in the coagulation and settling process. Produced water is chlorinated to reduce the biological activity but this step also serves as an oxidation step that causes the iron to begin to settle out of the water. Because the iron content is so high, the process needs a more focused step to bring the iron out of solution and separate it from the water. One such focused step is electrostatic coagulation.

Electrostatic coagulation involves applying a charge to aluminum plates in the presence of water to create aluminum hydroxide, which breaks down soluble hydrocarbons and causes the iron and other solids to coagulate. This allows the solids to take on a form where they can precipitate out in the settling tank along with other oxidized materials.

As for the settling tank, the only measurement is overfill protection using a point level sensor that will alarm if the level in the settling tank gets too high and there is a risk of overfill.

All of the instruments and analyzers communicate with some type of automation system that controls and monitors each area of the process. In most cases, high-speed two-way digital Fieldbus communications are used to connect instruments and analyzers to the automation system. If the instrument or analyzer doesn't offer a Fieldbus communications option, then a simple 4-20 mA current loop output is used to send the process variable to the automation system.

Instrumentation Considerations

Shifts in the chemical equilibrium occur due to changes in temperature and pressure -- and this can cause reactions that produce scale, solid hydrocarbons and changes in pH. A common industry concern is seen with oxygen deficient water, which causes elemental sulfur and iron to form when the water comes into contact with air, resulting in:

- Plugging of disposal wells by suspended solids and oil droplets

- Plugging of lines, valves, and orifices from inorganic scale

- Corrosion from acid gases

- ORP reactions with vessel and pipe walls

- Exceeding discharged oil permits

- Growth of bacteria that plug lines and valves or result in the formation of harmful products

Analytical equipment can continuously measure these changes to prevent such inconsistencies from damaging equipment. Some of the analyzers and instrumentation used for produced water treatment include:

Conductivity: Produced water, although having passed through a separator near the well site, will still contain significant levels of oil. The oil present in the produced water brought to the processing facility must be removed as efficiently as possible. Oil and water have marked differences in conductivity. By measuring the conductivity of the produced water through the oil/water separation process, an indication of separation efficiency is achieved. A toroidal conductivity analyzer provides this measurement.

Conductivity is also measured as water leaves the disinfection process to help identify the level of dissolved iron in the water. As the produced water leaves the disinfection process, the iron in the water will begin to coalesce to begin the precipitation process. Conductivity sensors can be used alongside pH and ORP sensors, using one common controller.

Total Dissolved Solids: Total dissolved solid measurements calculated from conductivity can be used to create the appropriate dilution factor required for further analysis in the quality of the water.

Biocide Addition (Chlorine): Produced water contains varied levels of bacteria. To destroy the bacteria, disinfection of the water is commonly performed using chlorine. In addition to the disinfecting qualities of the chlorine, its oxidation reaction causes iron to begin to precipitate out of the produced water. Monitoring the chlorine levels ensures the proper level of chlorine is maintained. The chlorination process also includes ORP, conductivity and pH measurement. A complete chlorine monitoring system integrates the chlorine sensor, pH and flow cell to ensure an accurate chlorine measurement.

pH and ORP: Due to high chloride levels, pH and ORP sensors are needed. ORP is measured before and after the addition of chlorine to properly control the addition rate and oxidation potential. Because chlorine can poison pH and ORP sensors, probes with a small ceramic reference junction are used to resist poisoning and to provide more durability in this environment. The disinfection process is optimized by maintaining a controlled oxidation potential, pH level and chlorine level.

Ceramic sensors are well suited for abrasive and corrosive applications. The pH sensors use a ceramic sensor, and flush-mounted ceramic pressure sensors eliminate buildup, erosion and poisoning.

Because pH and ORP sensors are easily poisoned in this application, it's important to monitor the sensors and be ready to replace them quickly. Endress+Hauser pH and ORP sensors with digital Memosens technology have built-in diagnostics that detect problems, and allow fouled sensors to be replaced with a pre-calibrated sensor with minimal effort. Both sensors can be controlled with one common transmitter, reducing the total system cost and component count.

Iron: The amount of iron in produced water can vary based on the geology of the well area, as well as other factors. While all produced water contains some level of iron, some produced water has significantly high levels that cannot go untreated and must be closely monitored. If left untreated, iron in the final water is a detriment to piping systems as it precipitates out from the water. High iron levels can limit the usage of the final water. The iron level in the final product is monitored using an iron analyzer.

An iron analyzer is a compact photometric analysis system for iron measurement commonly used in drinking water and waste treatment plants, and is a required addition for many produced water applications.

Flow: Electromagnetic flowmeters and ultrasonic flowmeters are two preferred technologies used in volumetric based measurements for produced water applications. The decision between electromagnetic and ultrasonic flow meters is dependent upon the customer's preference and the specific site application requirements.

For example, oil is not conductive, so during those steps in the process where significant amounts of oil are still present in the water, an electromagnetic flowmeter cannot be applied. Application details are critical to the site user in making an optimal economic and technically viable selection for this measurement point.

Level: Initial holding tanks, final holding tanks and many process and intermediate holding tanks must be monitored for proper level. Guided-wave radar level sensors are widely used for continuous level measurement of tanks as well as for detecting the interface between oil and water -- two fluids with different dielectric constants.

Additionally, point level sensors, also known as level switches, are used in a number of applications, such as settling tanks, to ensure these tanks do not overfill.

Temperature: Although heating or cooling are not typical processing steps in produced water treatment applications, the temperature of the fluid is monitored during the process. The final water temperature is monitored to ensure the temperature does not exceed pre-determined levels. Standard temperature sensors and instruments are generally suitable for produced water applications, although special concern must be taken in some instances due to harsh conditions.

Pressure: A common processing step for produced water is filtration. Produced water is filtered as it is received in a processing facility, as it moves through stages in the process, and as it leaves final settling to clean water storage tanks. Removal of solids through filtering at various stages of the process ensures solids will not plug processing systems or harm key processes.

Pressure measurement is used across these various filtering steps to monitor pressure differentials that can indicate a degraded or plugged filter system. Filter efficiency can significantly impact system throughput. With differential pressure (DP) monitoring, filters can be cleaned and replaced prior to a failure state.

Differential pressure measurements typically involve two pressure sensors and a transmitter that calculates the differential between the two sensors. If a produced water plant is subject to environmental extremes -- especially freezing in the winter -- then it will be necessary to heat trace the capillary tubes connecting the two sensors to the transmitter.

Summary

Produced water processing involves a number of mechanical and chemical processing steps. A range of measurement technologies including level, flow, pressure, temperature, conductivity, pH, ORP, chlorine and iron analysis are required. These measurement devices are connected to an automation system, usually via a Fieldbus interface, allowing the automation system to perform the required control, monitoring and operator interface.

Having one supplier who can provide all the required sensor technology reduces the time, effort and cost of equipping a produced water processing facility. Cost reductions are also realized by leveraging digital technology and common transmitter platforms. Service and support can be enhanced by turning to one supplier for virtually all instrumentation.

Most produced water applications will pose significant challenges in terms of measurement of various parameters, and these challenges will often require expert advice. The selected instrument and analyzer suppliers should be able to provide the necessary expertise, assuring the end user of reliable long-term operation.

About the Author: Steven Smith has spent the past 25 years consulting on process instrumentation and control, working in industry leading Fortune 500 instrumentation companies. Smith obtained his BS Degree from the University of Wisconsin and an MBA from the University of Colorado. He is currently the Western Region Analytical Product Business Manager for Endress+Hauser USA, responsible for technology application and business development for a wide range of analytical products.