Veolia Water Technologies supplies Kraft Heinz China with in-house wastewater treatment

CHINA, DEC 18, 2018 -- Kraft Heinz China has selected Veolia Water Technologies to provide the multinational food manufacturer with a wastewater treatment solution for its new soy sauce plant in Guangdong, China. The implementation of Veolia's technologies at Kraft Heinz's new plant in Guangdong will enable them to meet the stringent national and provincial discharge standards.

An American food company formed by the merger of Kraft Foods Group and Heinz in 2015, Kraft Heinz is the fifth-largest food and beverage company in the world. The new Kraft Heinz Yangjiang food factory in Guangdong covers an area of over 13 hectares, and will produce about 125,000 tons of soy sauce per year.

"This project is a testament to the quality of Veolia's wastewater treatment solutions and it reaffirms Veolia's leading position as a water and wastewater solutions provider", shared James PENG, Managing Director, Solutions China, Veolia Water Technologies. "By combining our technologies and our knowledge of local discharge limits, Veolia is able to help Kraft Heinz mitigate wastewater challenges in an increasingly environmentally conscious market".

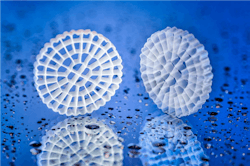

Veolia will provide its AnoxKaldnes Biological Activated Sludge™ (BAS) solution in the Kraft Heinz Yangjiang factory. Optimally designed to provide a volumetric loading capacity that is up to three times higher than conventional activated sludge, the BAS™ biological wastewater treatment solution is a combination of Veolia's compact AnoxKaldnes™ Moving Bed Biofilm Reactor (MBBR) and activated sludge processes. This will allow Kraft Heinz to cope with an overall higher organic load than conventional activated sludge processes, while requiring a relatively small footprint.

Apart from the AnoxKaldnes BAS™ solution, the wastewater treatment plant will also be equipped with a Dissolved Air Floatation (DAF) clarifier system for total phosphorous removal and biological sludge separation.

PENG concluded: "As Veolia continues to expand its presence in Asia, we are confident that our robust solutions and long-term focused customer service will continue to benefit customers across various industries. With a competent and strong professional team providing local support in China, we are excited about future growth opportunities here".

Veolia Water Technologies provides the complete range of services required to design, build, maintain and upgrade water and wastewater treatment facilities and systems for industrial clients and public authorities. The company's extensive portfolio of technologies features everything from online diagnostic solutions to evaporation and crystallization, energy-producing sludge treatment, state-of-the-art desalination, laboratory-grade water and mobile water services. By optimizing both processes and monitoring, Veolia Water Technologies helps clients reduce their water footprint while generating considerable savings in energy and chemical consumption. www.veoliawatertechnologies.com

Veolia group is the global leader in optimized resource management. With nearly 169 000 employees worldwide, the Group designs and provides water, waste and energy management solutions which contribute to the sustainable development of communities and industries. Through its three complementary business activities, Veolia helps to develop access to resources, preserve available resources, and to replenish them.

In 2017, the Veolia group supplied 96 million people with drinking water and 62 million people with wastewater service, produced nearly 55 million megawatt hours of energy and converted 47 million metric tons of waste into new materials and energy. Veolia Environnement (listed on Paris Euronext: VIE) recorded consolidated revenue of €25.12 billion in 2017. Learn more at www.veolia.com.