McIlvaine: Cement industry purchases to boost scrubber industry to $6.5B in 2012

NORTHFIELD, IL, Oct. 8, 2009 -- The market for industrial stack gas scrubbers has historically been small compared to those used in coal-fired power plants. But, thanks to tough proposed regulations for the cement industry, the world industrial scrubber market is now forecasted to reach $6 billion in 2012. This is the latest forecast of the McIlvaine Company in Scrubber/Adsorber/Biofilter World Markets.

A new proposed air pollution rule in the U.S. would require installation of scrubbers on more than 200 cement kilns. Some revenues are generated on order placement with the balance generated through the 24 months of a typical project length.

Another big market is waste-to-energy. There are typically two scrubbers in these plants. One captures hydrogen chloride and the other captures the SO2. China has embarked on a major program to burn its garbage. The U.S has also awakened to the advantages of using waste as a substitute for coal in energy production.

The biggest growth over the next decade will be in Asia. Scrubbers are the basic air pollution control device in developing countries. Foundries, steel mills, mining operations, and pulp mills all use scrubbers whether they are located in a poor Asian nation or in a rich one in the West. However, most of the construction of basic industry is taking place in Asia.

There is major stimulus funding for municipal wastewater treatment plants in China, the U.S. and some other countries. Sewage treatment generates noxious odors. A large treatment facility may purchase a number of scrubbers with a total outlay of over $1 million.

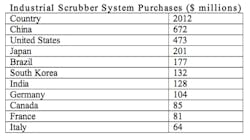

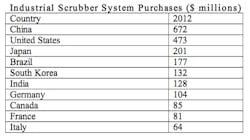

China will buy 50 percent more industrial scrubbers in 2012 than the U.S. Its purchases will equal the U.S. and Japan combined.

For more information on Scrubber/Adsorber/Biofilter World Markets, visit: http://www.mcilvainecompany.com//brochures/air.html#n008

###