WEFTEC.19 Show Preview

The 2019 Water Environment Federation Annual Technical Exhibition and Conference (WEFTEC.19) — considered the largest annual water quality event in the world — will take place Sept. 21-25, 2019, at the McCormick Place, Chicago, Ill.

This is the event’s 92nd year in operation, and with a wide range of programming topics to cover and events to attend, there is something for everyone in the water sector. More than 20,000 people register for the event each year. Attendees travel from all corners of the globe to meet with thought leaders and attend technical sessions — in fact, more than 3,000 registrants from more than 80 countries attended the event last year.

This year, WEFTEC’s theme is ReGeneration Workforce, with the goal to work together to “regenerate and reinvigorate the water workforce, providing solutions for workplace development, diversity and inclusion in the water sector.”

Programming will kick off on Monday, September 23 at 8:30 a.m. with the Opening General Session, featuring a keynote presentation form Dr. Lera Boroditsky, an associate professor of cognitive science at the University of California, San Diego. Boroditsky will discuss workforce development, diversity and inclusion as it relates to the water industry. She will share her research into how differences in language can shape the way individuals think, perceive and respond to each other, and improve the way we work together.

Additional event programming includes a wide range of topics for everyone in the water industry, including: collection systems (management, operations and maintenance, infrastructure, overflow reduction, wet weather planning, watershed approaches, and regulations); energy conservation and management (resource recovery, combined heat and power, biogas optimization); membrane technologies (application in wastewater and water reuse, innovations, enhanced performance, regulatory compliance); plant operations and treatment (innovations, technologies, processes, and proven solutions in water and wastewater treatment, including nutrient removal and odor control); regulations (CMOM/SSO rules, TMDL/watershed rules, nutrient trading, and NPDES Phase II); and more.

In the exhibit hall, companies from across the globe will present their technologies and services. This is the ideal place to meet with vendors and other industry members to solve complex problems and brainstorm solutions. The eighth annual Innovation Pavilion, located in booths 7947, 8048, 8240 and 7739, is the place to find the latest water sector innovations and provides access to the leaders and the technologies making it all happen. WEF has partnered with BlueTech Research and Imagine H2O to present the Innovation Pavilion and Theater to showcase water technologies of the future.

Other highlights of the event include the WEFTEC Discovery Zone and Pure Water Brewing Innovation Neighborhood, featuring a beer garden serving samples of beer brewed with recycled water, and kiosks from startups driving innovation in the water sector.

The following pages contain a sneak peek at some of the products and services that will be on display in the exhibit hall. For more information, visit www.weftec.org. IWW

Improve water quality with Vaughan Company’s Self-Priming Chopper Pump (handling heavy consistencies without plugging or dewatering of the solids) and the popular Vaughan Conditioning Pump (submersible chopper pump mounted on a portable stand with a high-velocity mixing nozzle).

Vaughan Company

www.chopperpumps.com

Booth 1017

Rental blowers

Aerzen Rental specializes in temporary oil-free blower and compressor solutions under 50 PSIG. A more efficient solution than renting plant air compressors, Aerzen Rental specializes in emergency response and long-term capital avoidance. Aerzen Rental provides best-in-class packages engineered for aggressive rental environments with on-board VFDs, remote monitoring, and outdoor builds with sound attenuating enclosure as standard. From rental units for immediate deployment in the event of a production failure or shortfall to operational leasing and contracting, Aerzen Rental is your expert partner.

AERZEN USA

www.aerzenrentalusa.com

Booth 862

Scaletron Industries is a leading manufacturer of corrosion-resistant scales and volumetric feeders designed for weighing, dispensing and monitoring the usage of chemicals in water treatment, wastewater treatment and industrial applications. Products include 150 lb and Ton Cylinder Scales; Drum, Tank, Platform and IBC Tote Scales; Spill Containment Scales; and Volumetric Screw Feeders.

Scaletron Industries

www.scaletronscales.com

Booth 5248

The AquaPrime® filtration system offers several advantages when utilized in industrial primary treatment applications including reduced energy costs in the secondary biological treatment process due to high TSS and BOD removal percentages, which reduce the organic loads. In addition, the space requirement of AquaPrime is very small compared to conventional sedimentation processes resulting in a footprint of approximately 20% of conventional sedimentation.

Aqua-Aerobic Systems Inc.

www.aquaprimefiltration.com

Booth 2234

Group 11 rotary damper drives and actuators offer the benefit of a total control package, utilizing reliable electronics to match the speed and precision of your process instrumentation. Standard Group 11 modulating drives are equipped with Beck’s Digital Control Module (DCM), which controls the position of the drive according to the input signal it receives. A position feedback signal is delivered to the DCM from the position sensing device. This signal is continuously compared to the demand input signal. A change in the input signal results in an immediate repositioning of the drive to balance the two signals.

Harold Beck and Sons

www.haroldbeck.com

Booth 8315

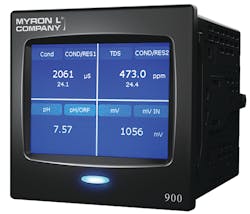

Myron L® Company’s new 900 Series Monitor/Controller combines flexibility, accuracy and reliability. Its 3.5”, resistive, touchscreen and intuitive graphical user interface make it simple to use. Measurement capabilities include: conductivity, resistivity, salinity, TDS, pH, ORP, temperature, mV, flow, and % rejection. It includes a 4-20 mA input and a variety of outputs: 0-10 VDC recorder output, relay output, alarm output, and optional outputs for 4-20 mA, RS-485, 2 additional relays, and 1 additional alarm output.

Myron L® Company

www.myronl.com

Booth 8327

Sherwin-Williams Protective & Marine Coatings offers Dura-Plate® 6000, a 100% solids, high-build, high-strength, reinforced epoxy lining for concrete and steel in severe wastewater service environments. The durable lining delivers time and cost efficiencies with fast return-to-service times and the option for single-leg application. It also features extremely low permeability and excellent chemical resistance to extend asset lives.

Sherwin-Williams Protective & Marine Coatings

http://protective.sherwin-williams.com

Booth 4060

Proco Style 711/731ProFlex™ check valves are engineered for installation onto pre-existing pipelines where the outfall invert is close to the floor of a manhole or outfall. Its “low-slope” design allows the valves to be engineered into the pipe layout with little concern for outfall clearance.

Proco

www.procoproducts.com

Booth 4227

Assmann Corporation of America’s double wall tanks are designed for primary and secondary containment of hazardous and corrosive chemicals in one unit in capacities from 20 to 8,850 gallons. The company’s patented Full Drain Outlet (FDO) assemblies for tanks of 2,500 gallons and larger allow tanks to drain without the need for mechanically installed nozzles. Assmann offers a full line of corrosion- and chemical-resistant tanks and containers constructed from crosslink or linear polyethylene, including vertical, horizontal and conical, and other double wall tanks, secondary containment basins and chemical feed stations in capacities ranging from 40 to 12,000 gallons.

Assmann Corporation of America

www.assmann-usa.com

Booth 4457