Use of treated sewage effluent as cooling tower makeup water – A pilot study

Open-recirculating evaporative cooling towers are the most commonly used and cost-effective cooling technology for commercial air conditioning and industrial processes. Water evaporation within the cooling tower accounts for most of the heat rejected, typically 75–80% of the total heat removed. Cooling towers can consume 20–30% of a facility’s total water use. Thus to minimize the dependence on freshwater sources for cooling tower operations, the use of alternative water supplies and water reuse initiatives are increasingly being considered by industries.1, 2

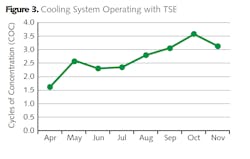

Treated sewage effluent (TSE) can be considered an alternative water supply for industrial operations. There are concerns that TSE may pose challenges to cooling tower operations with respect to enhanced biofouling, corrosion, and scaling.3 The water quality also determines the cycle of concentration (also known as concentration ratio) of the operation, indicating how efficiently water is recirculated in a cooling tower before being lost to blowdown. An increase in the cycle of concentration (COC) reduces water consumption by reducing makeup water volume, and wastewater generation (blowdown). Thus a critical understanding of the water quality and operational performance of a cooling system using TSE as makeup water through long-term pilot testing is a contemporary research need.

This article will present the findings of an eight-month long pilot study on the application of TSE for cooling tower operations.

Pilot Plant Description

The TSE was generated from an activated sludge wastewater treatment process followed by filtration and disinfection. Major water quality parameters of TSE are: total dissolved solids (TDS) of 1,500 mg/L, 106 mg/L calcium, 41 mg/L magnesium, 300 mg/L sulfate, 105 mg/L bicarbonate, 310 mg/L sodium, 528 mg/L chloride, 5 mg/L total organic carbon (TOC), and 8 mg/L phosphate.

Figure 2. Scale deposition on condenser surface with groundwater.

The pilot test was conducted with an open loop system cooling tower of 1,200 tons Btu capacity, as shown in Figure 1. Continuous disinfection of the recirculating water was achieved with 12.5% sodium hypochlorite solution as a primary biocide. In addition, a proprietary corrosion inhibitor was injected in the cooling tower cells for managing corrosion control. Also, a non-oxidizing biocide, isothiozoline, was used to control algal growth. Online analyzers were used for monitoring residual chlorine, pH, and temperature of the recirculating water. Chlorine residual in the range of 1.5–2.5 mg/L and pH in the range of 6.8–7.9 were maintained.

Water Quality Monitoring

The TSE feed line (FL) and circulating line (CL) water quality were monitored and analyzed for complete geochemical analysis on a monthly basis. In addition, microbiological organisms were monitored for biohazard assessment, including Legionella sp., Klebsiella pneumoniae and coliforms, with samples collected from the back end of the recirculating process to reflect worst case condition. All analysis was conducted by local accredited third-party laboratories. In addition, an assessment of enteric viruses was also performed by King Faisal Hospital & Research Center to evaluate the associated risks during the 8-month pilot study.

Cooling Tower Operation with Groundwater

Prior to the pilot testing with TSE, groundwater was used for the cooling tower. The groundwater characteristics consisted of a TDS level of 3,040 mg/L, including scale-forming ions such as calcium (233 mg/L), magnesium (97 mg/L), sulfate (558 mg/L), and bicarbonate (226 mg/L). The COC with groundwater was limited to 2, due to higher concentration of scale-forming ions. The cooling system’s condensers operated with groundwater were visually inspected as shown in Figure 2. Severe scaling was observed on the condenser surfaces with groundwater as makeup. The formation of scale could potentially reduce the heat transfer through the exchanger and cooling load, and increase pressure drop and condensing pressure. The increase in condensing pressure may increase the compressor's load to achieve the lift between the evaporator and the condenser; this will reduce the chiller’s coefficient of performance.

Cooling Tower Operation with TSE

The inorganic chemical water quality of TSE was better than groundwater with a TDS of 1,500 mg/L. The Langelier Saturation Index (LSI) values varied from 0 to 0.5, indicating that the scale-forming tendency of TSE is low and, consequently, the cooling tower can be operated at higher COCs. The pilot study results suggested that the COC of the cooling tower operation could be almost doubled (from 2 to 3.5) with TSE as makeup water as shown in Figure 3. Higher COC means less blowdown frequency and reduction in water demand. This operational improvement can be explained based on inorganic scaling formed on AC plant accessories.

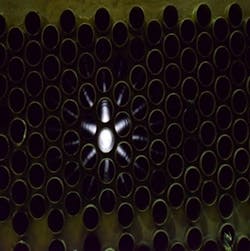

The condenser surfaces during the use of TSE are shown in Figure 4. The condenser surface was clean without mineral deposit formation when TSE was used. The visual comparison of Figures 2 and 4 clearly show the potential operational benefits of utilizing TSE as makeup water.

Figure 4. Condenser surface of the cooling system operated with TSE.

Biohazard Assessment of TSE on the Cooling System

Water samples were collected from raw sewage, treated wastewater, makeup TSE water, and the cooling tower circulating line. During the course of the pilot, representative water samples from the cooling tower were analyzed for Legionella sp., Klebsiella and total coliforms on a monthly basis. The analytical results showed that all water samples were negative for these critical pathogens (none observed).

An assessment of enteric viruses (e.g., norovirus, adenovirus, astrovirus, rotavirus, sapovirus) was also conducted during the course of the pilot study. Enteric virus analyses were conducted bi-weekly during the 8-month period. All the raw sewage samples contained enteric viruses. None of the samples collected from the cooling tower system operation indicated presence of enteric viruses. The results demonstrated that the disinfection and biocide treatment was effective in controlling risks to human health.

Conclusions

The outcome of this pilot study indicated that treated sewage effluent is a viable and sustainable alternative to groundwater as cooling water makeup in industrial cooling systems. The biohazard assessment indicated that the disinfection treatment was effective in controlling risks to human health.

Application of the TSE could save a significant amount of water, energy, and operating costs for cooling tower operations. The increase in COC resulted in a 27% reduction in water demand from the current groundwater baseline. The annual expected makeup water savings for the 1,200-ton AC plant is estimated at 16,501 m3. Consequently and based on the positively achieved performance during the pilot testing, several AC plants with a total cooling capacity of 6,000 tons are currently being considered for the application of TSE, which will equate to annual savings of 82,505 m3 of groundwater. Further, the annual expected energy savings is 82,505 KWh.

It is important to note that any facility that intends to use TSE in open cooling system should go through an evaluation step for proper selection of chemicals/biocides, understanding of TSE water quality, and optimization of the cooling system operation treatment accordingly. WT

About the Authors: Mohammad Badruzzaman, PhD, PE, BCEE, is a water treatment expert with Saudi Aramco Environmental Protection in Dhahran, Saudi Arabia. Dr. Badruzzaman is a licensed professional engineer with 15 years of experience in water conservation and treatment, and is also a board-certified environmental engineer by the American Academy of Environmental Engineers and Scientists. Dr. Javeed Mohammed Abdul and Abdulaziz Al-Malki are water treatment engineers with Saudi Aramco's Process and Control Systems Department (Dhahran, Saudi Arabia). Fawaz Al-Wohaib and Nidal Samad are both with Saudi Aramco's Environmental Protection division (Dhahran, Saudi Arabia). Fadel I Jutail is a foreman with Saudi Aramco's Abqaiq Community (Abqaiq, Saudi Arabia).

References

- Badruzzaman, M., C. Cherchi, M. Kessano, K. Schwab, and J. Jacangelo. "Multipurpose reuse of reclaimed water at an electric utility and for wetlands rehydration in Florida," report published by the Water Research Foundation (WRF), ISBN: 978-1-60573-345-9, 2018.

- Oppenheimer, J., M. Badruzzaman, C. Cherchi, J. Weakley, J. Pohl. "Drivers, Successes, Challenges, and Opportunities of Onsite Industrial Water Reuse: A Path Forward for Collaboration and Growth," Water Reuse Research Foundation, 2015.

- San Diego County Water Authority. "Technical information for cooling towers using recycled water," 2009.