SUEZ to supply SRU to Statoil; Schneider Electric pursues zero-energy grant; Rawwater adds manager

SUEZ’s seawater sulfate reducing nanofiltration membranes and ultrafiltration system selected by Statoil

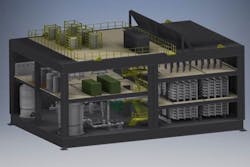

SUEZ will supply its seawater sulfate-reducing nanofiltration membranes and ZeeWeed 700B horizontal ultrafiltration system for the Johan Castberg (formerly Skrugard) project located in Norway, about 100 kilometers north of the Snøhvit field in the Barents Sea. Statoil awarded a consortium, led by SUEZ and Halvorsen TEC, the contract to supply the equipment and complete the project. Signing of the equipment contract follows a year-long front-end engineering design (FEED) program, where SUEZ and Halversen TEC demonstrated the feasibility of the technology and associated expertise to meet project needs. The seawater sulfate removal unit (SRU) will allow Statoil to inject seawater at less than 20 parts per million of sulfate content and less than 20 parts per billion of oxygen. The SRU’s injection capacity will be 1,188 cubic meters per hour.

The SUEZ-Halvorsen TEC SRU package will include:

• SUEZ’s seawater sulfate reducing nanofiltration membranes, which eliminate nearly all sulfates from the injection seawater, remove divalent ions from the seawater to prevent barium and calcium scale formation while leaving monovalent ions like sodium and chloride to pass through the membranes.

• SUEZ’s ZeeWeed 700B horizontal ultrafiltration system, which has been adopted in the desalination industry and provides fine solids removal.

• Deoxygenation membrane technology from 3M.

• Full single-lift SRU.

The SRU will be installed on a floating production, storage and offloading vessel. During production, seawater is injected into oil reservoirs to maintain or enhance oil production. However, because low-quality injection water can cause scale and corrosion that will plug and sour the field, operators first process the seawater.

The equipment is expected to be delivered in the beginning of 2020, while the first oil is expected to be produced in 2022.

Schneider Electric pursues grant for net zero energy at wastewater plant

Schneider Electric announced it has been selected to pursue a $2.7 million grant from the California State Water Resources Control Board to help fund an infrastructure improvement project at the City of Anderson’s Water Pollution Control Plant. When approved, the proposed project will improve energy efficiency in the plant’s aeration process and add a solar array that will make the plant a net zero energy facility. The grant will be used to install aeration controls to improve accuracy and reduce energy waste during the wastewater oxidation process. These improvements will reduce the plant’s utility costs by 25 percent. The remaining balance of the plant’s annual utility costs will be entirely eliminated through the installation of a 539-kilowatt solar array. In total, the upgrades will improve plant performance and generate $4.7 million in savings over the life of the project.

Construction is expected to begin September 2018.

Rawwater appoints business development manager

Rawwater appointed Mike Mooney as business development manager. Mooney is a chemical engineer with 25 years of expertise in specialty chemicals, integrity management and flow assurance up and downstream in the oil and gas industry. He has worked onshore and offshore in Europe, the Middle East and Africa. Before joining Rawwater, he was a business development/sales manager with oilfield chemicals specialists Reda Oilfield. Prior to that, he provided specialist consultancy services globally.

In addition to the arrival of Mooney, Rawwater’s research department has also been strengthened through the recruitment of several new specialists, including bioreactor technicians and a biocorrosion technologist.

The Rawwater Group offers contract research and consultancy in the fields of materials science, well technology and water management and combines engineering with reservoir microbiology to deliver solutions for facilities design, oilfield souring, biofouling and microbial corrosion.