Anaerobic treatment: a Growing Appetite in Industrial Applications

Industrial food and drink producers are increasingly turning to anaerobic treatment processes as an emerging technology of choice due to innovative improvements.

By Steve Gluck

There is growing interest in anaerobic treatment (AnT) of wastewater for industrial processes, particularly for food and beverage production. While it is more expensive, it has a number of advantages over its aerobic counterpart, including the production of usable energy in the form of biogas, lower energy demands, smaller footprint and less sludge production.

However, as a technology AnT has often been seen as complex, and vulnerable to “shock loads”, in which the microbial community at the heart of the process can be damaged by sudden changes in the quality of the incoming wastewater, for example pH levels or FOG (fats/oils/grease) content. Changes in chemical oxygen demand (COD) can also be damaging. These kinds of swings are very disruptive and are a common problem in batch-orientated, industrial processes such as food and beverage operations.

Industries with high levels of COD in their wastewater, such as dairies and brewing, and to some extent pulp and paper, are being targeted by a range of younger, innovative companies offering new twists on traditional AnT.

Who’s who

The most commonly used conventional AnT solutions are the UASB (Upflow Anaerobic Sludge Blanket) or EGSB (Expanded Granular Sludge Blanket). This market is dominated by the established players, including Pacques, Nijhuis, HydroThane, EMG, Waterleau, Evoqua, EnviPure, Econvert and Veolia’s Biothane.

The conventional technologies are the most dominant in the marketplace and have, as should be expected, incremental improvements on a relatively mature technology. The biggest unmet needs are for upflow reactors, and include instability with pH, FOG, salinity or load changes, and design complexity impacting capital and operating expenses.

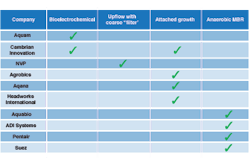

Four technology domains offer the most potential for breakthrough performance, including the use of bioelectrochemical technology, upflow reactors (which have a coarse type of media to prevent overflow of suspended growth), attached growth reactors, and anaerobic MBRs (which work in conjunction between mixed suspended growth reactors and ultrafiltration or microfiltration). These classifications are shown in Table 1.

Table 1: Newer AnT solutions by technology type

A particularly interesting company in terms of addressing AnT’s pain points, is NVP Energy, based in Ireland, which offers one of the only solutions able to operate effectively in cooler temperatures. Most methane-producing bacteria can only operate at mesophilic temperatures, i.e. in the 20-45°C range. Colder temperatures reduce microbial growth rates and increase methane solubility, making it harder to harvest biogas.

NVP claims to have solved this problem by selecting specific psychcrotropic organisms, which can process wastewater as low as 4°C, via its system design and operating conditions, as well as supplying microbes directly.

The company is planning a pilot installation in the second half of 2018 at a leading UK wastewater utility to treat municipal wastewater. This is a unique placement for anaerobic treatment for ambient temperature municipal markets, and if successful, could be a game-changer.

Another company that stands out is Cambrian Innovation, which offers a fixed film anaerobic biological treatment unit, augmented by bio-electrochemical output to enhance methane (microbial electrolysis cell technology) conversion.

It offers wastewater treatment as a service under a WEPA (Water-Energy Purchase Agreement) – a Build-Own-Operate service agreement in which the client pays only for the volume of water treated. The company has four installations at Lagunitas Brewing Company; Bear Republic Brewing Company and Rombauer Winery, all in California.

Industrial challenges

All the “challenger” companies listed above have the food and beverage market as a target. Pulp and paper also represents a market with similarly high COD wastewater, but it may have too low capital to invest in new equipment in the current industry cycle. In addition, some chemical and pharmaceutical wastewater is amenable to these technologies. The most common unmet needs are: minimization of by-product solids, rapid treatment, robust operation, energy neutral or energy-producing and relatively low cost to treat.

Market potential

Although anaerobic wastewater treatment is increasingly seen as a competitive option versus aerobic treatment, the technologies listed above have yet to take significant market share away from upflow reactors.

However, given the sustainability drivers of energy efficiency, carbon footprint and water reuse, these new options will certainly help expand the market adoption of anaerobic treatment and possibly take some of the growth away from upflow reactors. As with major providers such as Evoqua, Veolia, and Suez, these newer solutions may end up in their portfolios as alternatives to existing solutions. Indeed, although at a much earlier stage, Fluence is pursuing early stage work in new electrogenic bioreactors while Eisenmann offers an AnMBR (anaerobic membrane bioreactor).

The food and beverage industry, taking into account dairy, brewing, and meat and poultry, represents an estimated $696 billion in Europe and $415 billion in the US, while the pulp and paper industry represents $103 billion in Europe and $80 billion in the US. Brewing generates approximately 161,000 and 386,420 tons of BOD per year in the US and the EU respectively. Thus, the market for anaerobic treatment should be strong in industry, particularly new builds, to minimise discharge loads to a municipality.

Verdict

Anaerobic treatment continues to be a treatment option with well-known benefits and challenges. The growth of such equipment has been limited in part by its complexity and perceived lack of robustness. Drivers for energy neutrality, water reuse and decreased footprint, along with improved stability are being addressed by the major suppliers but also a growing number of smaller companies, many of which are beginning to gain commercial traction.

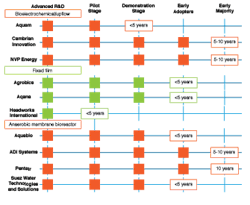

Figure 1. Timeline of progress to next commercial development stage

for selected anaerobic technology companies

Most of these companies have had commercial operations for under three years and thus they are at the point of accelerated growth should the market take hold. Everyone working in anaerobic treatment wants to deploy their technology in food and beverage applications and in particular, breweries followed by wineries, distilleries, confectionaries and soft drink manufacturers.

Anaerobic MBRs have the most promise for water reuse applications requiring reverse osmosis, because of the high level of filtration required for pretreatment. Nonetheless, because some materials are not effectively removed by anaerobic treatment, notably ammonia, such applications may require aerobic polishing. Whereas such a system would add complexity, it also improves treatment robustness.

For on-site treatment applications and particularly those discharging to a municipal plant, the attached growth or upflow systems with the retaining media show the most promise in competing with the incumbent UASBs or EGSBs.

Nonetheless, a sophisticated customer would prefer an incumbent with their ability to manage such reactors. A new adopter, seeking the robust and simpler technologies could do well with some of the newer companies.

Steve Gluck is the BlueTech technology assessment group expert. The latest Horizon Scan and Competitive Landscape Analysis report from BlueTech Research on anaerobic treatment is now available at inside.bluetechresearch.com