Iraq oil refinery to eliminate liquid waste with ZLD system

Iraq´s State Company for Oil Projeacts (SCOP) will use a zero liquid discharge (ZLD) to eliminate all liquid waste discharge from its Karbala refinery.

Veolia´s HPD evaporator technology was selected for the Karbala Refinery project by SCOP and its EPC contractor HDGSK, a joint venture comprising Hyundai Engineering & Construction, GS Engineering & Construction, SK Engineering & Construction and Hyundai Engineering.

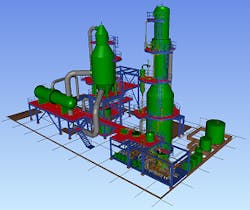

Veolia Water Technologies will engineer, procure and deliver a Zero Liquid Discharge system based on its proven HPD Brine Evaporator and Brine Crystallizer technologies for calcium sulfate seeded slurry processes.

Veolia’s system will be divided into two steps: the first step is a Brine Concentrator based on calcium sulfate seeded slurry and driven through a single Mechanical Vapour Recompression (MVR).

The second step is a Zero Liquid Discharge (ZLD) Brine Crystallizer driven through two stages of single MVR.

The plant will have a capacity of 55 m3/hr and is scheduled for delivery in August 2016.

The combined system will eliminate all liquid waste discharge and will produce a waste solid product discharge from a centrifugal separation process.

Waste solids from the plant will be routed to a landfill for disposal. The process distillate quality recovered from the process will be routed internally to the refinery for reuse.

Ignacio Martinez, vice-president and general manager of Veolia Water Technologies’ Evaporation & Crystallization activities, said: “The Karbala refinery is due to become the most technically advanced refinery in Iraq.”

###

Read more

Industrial markets to power Veolia Water’s Future

Veolia to supply all three water units for pulp mill expansion in Brazil