New Technology Aimed at Reducing Silica Contamination

By Rick Dunn

A new monitoring technology that is being applied in semiconductor ultra-pure water (UPW) systems to promote elimination of silica and other contaminants could have potential significance for power plant applications that could benefit from reduction of, or even elimination of, silica.

The presence of silica in boiler feed and steam systems has well-known negative consequences, both in terms of thermal efficiency and mechanical integrity. A relatively small reduction in thermal efficiency can result in significant financial losses as power output is reduced. Similarly, turbine downtime is associated with significant repair/cleaning costs and lost revenue due to lower power output.

Mixed-resin beds are commonly used to remove a broad range of contaminants, including silica. On-line silica analyzers monitor the effluent of mixed beds to provide indication of silica leakage and trigger regeneration of the beds. However, the most commonly used on-line silica analyzers demonstrate a limit of detection of approximately 0.5 µg/L, with a corresponding limit of quantitation of approximately 1.5 µg/L.

While the monitors are a practical method for monitoring silica limits in the power industry, power-plant water systems regularly experience levels of silica that, over time, will build up on heat transfer surfaces and turbine blades.

Boren Boron as a Precursor

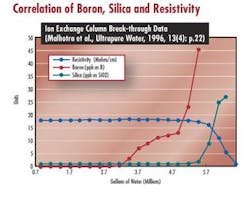

Several recent studies have documented that boron is released from UPW mixed-bed ion-exchange resins before silica. These studies have been conducted with a focus on the semiconductor industry, but the information has relevance for management of power plant water systems.

It is not the intent of this report to suggest that a detectable increase in boron should trigger a regeneration of mixed-bed resins, nor that boron is even a contaminant of interest for power plant systems. Boron monitoring is simply the mechanism by which to accomplish the goal of eliminating or reducing silica concentrations.

The chemical properties of boron are such that ion-exchange resins have a lesser effective affinity for boron than for other ionic species, including silica. In a typical water system, incoming water contains a variety of ionic impurities. As the resin traps these impurities, fewer and fewer resin sites are available to bind subsequent incoming impurities. Those impurities, however, do not simply pass through the ion-exchange bed and into the effluent. Instead, the resins will 'release' loosely bound impurities (i.e., boron) and bind in the ionic impurities for which the resin has a higher affinity.

Due to the resin's lower affinity for boron, the majority of ions initially released will be boron-based ions, followed by silica. The volume of water processed between the release of boron and release of silica is dependent upon many factors, including concentration of boron and silica in the feed water, CO2 concentration and transients, pH, etc.

Monitoring System

To address a growing interest in eliminating silica contamination (and provide protection for boron-sensitive processes) Ionics Instruments Business Group developed an on-line, continuously monitoring boron analyzer with a limit of detection of 15 ppt boron. The instrument not only detects the first compound to be released from mixed-bed resins, but does so at levels rivaled only by Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) or Ion Chromatography (IC), both of which are considerably more expensive.

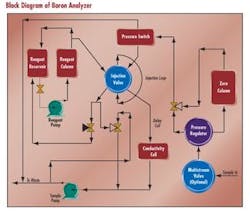

The determinative technique employs measurement of the conductivity difference between a boron free blank and the sample water. A polyol based reagent reacts with boron in the sample to produce a highly ionized complex that is then measured via conductometric technique.

A blank is obtained by routing incoming sample water through a "zero column" that contains a boron-specific resin and a mixed anion-cation resin. Boron and other ionic impurities are removed by the zero column, and the sample is then routed to a 6-port injection valve. A small volume of reagent solution is also routed to the injection valve. The sample and reagent mix in the injection loop and undergo a brief reaction period while in transit to the conductivity cell. Conductivity of the blank is measured and stored in the instrument's firmware.

A user-selected number of sample measurements is then conducted in a similar manner with the exception that the incoming sample is bypassed around the boron-removal column. Boron in the sample reacts with the reagent in the Injection Loop to form a boron-reagent complex that is highly conductive. The conductivity of the boron-containing sample is compared to the conductivity of the zero. An internal algorithm uses the conductivity difference to calculate a boron concentration. After every 10 sample measurements, the instrument automatically runs another zeroing sequence to calculate a new blank value.

To achieve the detection limit of 15 ppt, two key design features were implemented. First, the reagent is continuously recirculated through a deionizing column to keep background conductivity as low as possible. The reagent reservoir holds one liter of reagent, which lasts for approximately three months based on an analysis frequency of one sample every 12 minutes. The reagent resin column continually removes ionic impurities that may be picked up by the recirculating reagent. Reagent that is routed to the injection valve and used for analysis is not recycled; it is sent to waste.

The second design feature that enables for low part-per-trillion sensitivity is the selection of the proprietary reagent. The polyol compound reacts with boron in the sample to produce a highly ionized complex. The highly ionized nature of this complex allows for very sensitive measurements, even at extremely low levels of boron. Additionally, the reagent does not react with silica or other ionic species ensuring no contribution to conductivity from interfering analytes.

Because low background conductivity is essential for accurate and precise low-level measurements, the boron analyzer has an operating specification of >10 megohm-cm for incoming sample resistivity.

The analyzer provides a warning when sample resistivity drops below 15 megohm-cm as measured at the instrument's conductivity cell and ; the analyzer shifts to a standby condition when sample resistivity falls below 10 megohm-cm.

The analyzer is available in single and multi-stream configurations. On units that incorporate the optional on-board multiplexor, the analyzer will advance to the next available sample stream upon detecting a low resistivity condition on a given sample stream. On single-stream units, the analyzer will remain in standby as long as sample resistivity is below 10 megohm-cm, and then will restart automatically when resistivity returns to within specification. No operator action is required.

The analyzer also uses analog and alarm outputs to provide customized data and information to control and data acquisition systems. The analyzer's five binary inputs and four binary outputs provide for the ability to control the analyzer remotely and program process-corrective actions at customizable thresholds.

Field Testing Results

One of the primary goals of field testing was to demonstrate that the analyzer was capable of precision and accuracy comparable to that of an ICP-MS. In the summer of 2000, two boron analyzers were placed on-line on an operating, full-scale ultra-pure water system. The site also provided access to two ICP-MS instruments.

Boron standards were injected into a boron-free UPW sample stream using a dynamic dilution device. The dilution device uses a National Institute of Standards and Technology (NIST)-traceable accurate turbine flow meter, a precision syringe pump and a series of static mixers. The device diluted boron standards of 25 ppm and 250 ppm and injected them into the boron-free sample stream to achieve sample concentrations of 2.0, 1.0, 0.5, 0.25, 0.125, 0.085, 0.06, 0.05 and 0.03 parts-per-billion boron. These sample concentrations were measured by both on-line boron analyzers and both laboratory ICP-MS units.

The accuracy of the analyzer was demonstrated to surpass that of ICP-MS in the range of 0.088 ppb B to 2.0 ppb B, and comparable to ICP-MS in the range of 0.03 ppb B to 0.088 ppb B. Additional monitoring of the mixed-bed resins during normal operation, in conjunction with standard injections of boron, revealed no effect due to potential matrix interferences.

About the Author:

Rick Dunn is Product Manager for TOC instrumentation at Ionics Instruments. He is a former Engineer in the US Naval Nuclear Power Program, and has 7 years experience in water treatment and analysis. This article was adapted from a paper presented at the 2002 International Water Conference in Pittsburgh, PA. Dunn may be contacted via e-mail at [email protected].