Water Reuse for the Industrial Landscape

One Problem, Two Solutions, Multiple Benefits

By Barry Millar

Despite proven environmental and economic benefits, it’s disheartening that water reuse is yet to be widely adopted across the global industrial landscape.

Here, I set out to explore why this might be the case and also consider what it will take to break down some of the barriers to embracing rainwater harvesting and graywater recycling in a meaningful way.

One Problem

We are all aware of the impact of production processes on water supplies. Across Europe, 40 percent of total water abstractions are specifically for industrial purposes. While in the U.S., latest estimates suggest that 355 billion gallons of water are used each day in industry. When added to domestic and other commercial water usage, this amounts to a 1 percent increase in freshwater withdrawals globally every year since the 1980s. This steady increase has led to water scarcity affecting 40 percent of the global population, with even advanced industrial nations reporting occasional difficulties in meeting demand.

Of course, this isn’t all due to industrial development - ongoing climate change and advancing population density play important roles in the rising level of water use, too. However, as major users - and polluters of - water supplies, the world of industry could, and should, do more.

Four Barriers

So why is it that most organizations are failing to put water-saving measures in place? As is often the case, it comes down to money, technology, legislation and education.

First, let’s talk about money. Water is, let’s face it, incredibly cheap compared to most other commodities and so it often goes unnoticed as a relatively insignificant line on the profit and loss statement. In a still uncertain post-recession economy, there’s understandably also concern about up-front capital expenditure, payback times and the ongoing maintenance costs associated with deploying new, non-essential technologies.

From a technical viewpoint, reliability issues from early-to-market systems and insufficient track records of success do nothing to support the cause. The prospect of operational downtime incurred as a result of installing new systems - and traditionally the space required to do so - have no doubt further impeded progress.

There are broader issues around legislation and education, too. While some countries like Spain (which, like many of its southern European neighbors, has long experienced water shortages) have developed a supportive regulatory framework to stimulate the implementation of water reuse schemes, most nation-states have yet to do so. And, with a lack of education about what can be achieved, there’s no drive to do so either.

Taking all of these factors into consideration, it’s perhaps easy to see why the uptake of water recycling has been hindered. But before completely dismissing reuse, take time to consider the benefits.

Multiple Benefits

Let’s first consider the operational impact of an unavoidable interruption to water supplies: for most industrial operations, such disruption would be critical at best. Exploring options to create a sustainable, dependable and controllable source of water supply in times of emergencies or scarcity will assist with business continuity and stability.

Second, choosing water recycling or alternative water sources that reduce an organization’s environmental impacts will add tangible and measurable weight to its corporate social responsibility (CSR) efforts, ultimately improving its reputation with multiple stakeholders.

Finally, good water reuse systems will deliver an economic benefit that will outpace the initial outlay, not only reducing payback times but also lowering potable water use and overall costs. In addition to lower metered water bills, companies can also benefit from reduced risks of stormwater flooding, decreased sewerage charges and lower energy costs associated with water supply.

When you consider that rainwater harvesting can reduce mains water consumption by up to 30 percent and graywater recycling can save as much as 40 percent, financial directors could be forgiven for asking why these opportunities haven’t been acted upon sooner.

Two Solutions

My team and I at Waterscan have been working hard to break down the barriers to water reuse and have, as a result, created next-generation technologies for rainwater harvesting and graywater recycling which I believe will be of significant value to the industrial sector.

These technologies include:

- A triple-tiered redundancy back-up system to ensure total integrity of supply and consistency of performance with zero supply interruption through switching processes.

- Built-in telemetry that transmits system data and live diagnostics for preventative maintenance, significantly reducing the likelihood of switching to mains water.

- Variable speed, load-sharing pumps, insulation and slow-close valves for an exceptionally quiet operation.

- Low-energy components so the system can produce 1 m3 using just 1.5 Kw/h energy.

- A smaller system footprint, which reduces up-front installation costs and lowers the impact on the total property portfolio footprint.

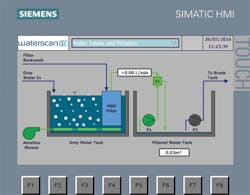

- Submerged membrane bioreactor filtration, which provides a fixed barrier to waterborne viruses and pathogens.

- Optimized aeration to stimulate a continual self-cleaning effect on the membrane surface, reducing maintenance requirements.

Rainwater Harvesting

Here, rainwater is collected, filtered and fed back into the property through a robust treatment system ensuring that only the cleanest water is utilized for non-potable purposes like vehicle washing, toilet flushing and irrigation. Such systems are ideally suited for industrial use where there is usually considerable roof area to harvest sufficient water to achieve a good return on investment.

Graywater Recycling

Graywater recycling captures the water used for showering or bathing and, after treatment through an ultrafiltration membrane system, is fed back into the property for non-potable purposes such as flushing toilets, irrigation and laundry.

There are two system designs to consider, based on company priorities:

- Batch System: Where low energy consumption is a priority and there is physical space for a larger system footprint, this low-pressure filtration method takes a little longer but uses less energy in the process.

- On-Demand System: Where saving space and realizing a faster return on investment are priorities, this high-pressure approach delivers rapid ultrafiltration and therefore requires less tank storage and correspondingly reduces installation costs.

Waterscan designs and builds its systems using modular components, meeting clients’ exact specifications in line with individual business strategies and site requirements.

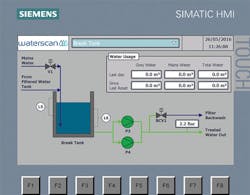

Waterscan systems also have a Siemens smart interface for usage data and enhanced system monitoring for basic end-user maintenance capability to reduce the likelihood of switching to mains water.

I consider these unique features to be important technical milestones in the bid to advance the adoption of water reuse across the industrial landscape. Indeed, it is now proven that, in combination with first-class consultancy, these new technologies can deliver most organizations a 30 percent faster return on investment compared to first generation water reuse systems.

That is not to suggest that one size fits all however: the flexibility to design systems that reflect clients’ commercial priorities is hugely important. It’s also fully justified for clients to demand total trust in their delivery partner, expect a fast return on investment and want complete confidence in the operational efficiency of their systems. Indeed, I regard these as critical success factors. I urge you not to let concerns based on early technologies hold you back: there are enormous potential benefits for those willing to take the plunge and embrace water reuse.

About the Author: Barry Millar is operations director at independent water consultancy firm Waterscan. To explore the potential benefits of rainwater harvesting or graywater recycling for your organization, visit www.waterscan.com or call +44 1243 839 880.