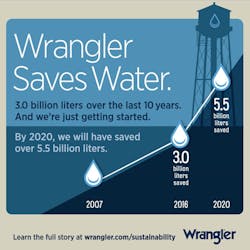

Denim company announces 3 billion liters of water saved since 2007

GREENSBORO, NC, DECEMBER 14, 2016 -- Wrangler® Jeans today announced the milestone of three billion liters of water saved since 2007. The global leader in jeanswear and casual apparel also announced a goal to reduce water usage at its facilities by 20 percent by the year 2020.

The three billion liters saved equals the annual household water needs of more than 21,000 Americans. Water plays a significant role in the manufacturing of denim. The finishing steps in producing a pair of jeans typically require multiple water baths. By merging steps, Wrangler reduced water use without compromising quality. This improved wash down process, combined with increased water recycling, yielded this significant resource conservation.

"Wrangler has always had a strong connection to the land, and a commitment to protecting our natural resources for future generations," said Tom Waldron, president of Wrangler. "Now, we are expanding our water stewardship program goals to further help reduce our impact and conserve the water resources of the communities where we operate."

The Wrangler brand's water recycling program invested in advanced wastewater treatment systems to improve effluent water quality. This allows treated water to cycle back through the system. For example, the company's owned Torreon facility in northern Mexico has achieved a 45 percent water-recycling rate through a combination of disc filtration and biological treatment processes. The company plans to invest in additional technology at the site to achieve a 75 percent recycling rate by 2018.

Wrangler first pioneered a major water conservation effort with its water miser program a decade ago. This finishing process applied detergent more strategically, reducing the water used in the company's wash formulas by up to 28 percent, a technique that was then applied globally across internal manufacturing. It's one of many initiatives that Wrangler has been doing for years, which the company is now sharing.

"Our company has a responsibility to play a leading role in moving our industry toward sustainable practices," said Roian Atwood, director of sustainability for Wrangler. "Reducing billions of liters of water usage represents one small part of our efforts to minimize our environmental impact. Our responsible chemistry strategy also safeguards water quality while our sustainable fiber program promotes responsible cotton growing practices concerning the use of water, pesticides and fertilizers."

About Wrangler®

Wrangler® apparel is available nationwide in mass market retailers, specialty stores, including work apparel chains, farm & fleet, and western stores, as well as through online and catalog retailers. To find a retailer or for more information on the Wrangler family of products, visit Wrangler.com or call 888.784.8571. This fall, Wrangler launched a new digital sustainability page to share information on its key programs, including this new global water reduction goal. Explore the content at Wrangler.com/sustainability.html.