Closing the loop: High-recovery RO and ZLD for a sustainable water future

Key Highlights

- High-recovery RO systems like MAXH2O Desalter achieve up to 98% recovery, preventing scaling and reducing costs.

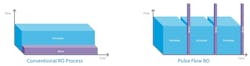

- Pulse Flow RO technology dynamically cleans membranes, significantly extending their lifespan and improving recovery rates.

- Hybrid ZLD approaches combine advanced membranes with thermal polishing to minimize energy use and environmental impact.

- Innovations address common challenges such as fouling, osmotic pressure, and operational stability, enabling industrial water reuse.

- These technologies support industries in meeting strict environmental regulations while reducing freshwater demand and waste.

Across industries, the move toward sustainability is no longer optional — it is essential.

Water, the foundation of industrial activity, is under unprecedented pressure. As freshwater sources dwindle and environmental regulations tighten, the vision of a waste-free, circular water economy is quickly becoming an operational priority.

That vision is now attainable through high-recovery reverse osmosis (RO) and zero liquid discharge (ZLD) technologies — innovations that transform wastewater from an environmental challenge into a reusable resource.

From waste to resource: The role of ZLD and MLD

A true ZLD system ensures that no liquid waste leaves the plant — only purified water and minimal solid residue. But achieving this goal requires a practical bridge: Minimum liquid discharge (MLD).

MLD systems significantly reduce brine volume before the thermal stage, lowering both energy consumption and operational costs, and making ZLD viable at industrial scale.

Traditional RO systems typically recover only 50–80% of feedwater, leaving a concentrated brine stream rich in salts, organics and metals. Without advanced treatment, this stream is often discharged, harming soil and groundwater.

To close the loop, industries need reliable, high-recovery RO systems capable of treating complex wastewater efficiently.

The challenge of high recovery

Increasing water recovery rates introduces several engineering challenges:

- Scaling and fouling: Higher concentrations of dissolved solids lead to mineral and biological buildup.

- Rising osmotic pressure: Increased pressure raises energy demands and membrane stress.

- Operational stability: Even minor performance fluctuations can impact production.

- Chemical and energy costs: Aggressive recovery targets can drive up OPEX without the right controls.

Reaching ultra-high recovery requires not just stronger membranes, but smarter process design — and IDE has developed a breakthrough solution to make it possible.

The MAXH2O technology platform

IDE Technologies’ MAXH2O platform is a suite of proprietary membrane-based technologies designed to push water recovery to its practical limit — safely, efficiently and sustainably.

The platform includes two key innovations:

- MAXH2O Desalter

- MAXH2O Pulse Flow RO (PFRO)

Together, they deliver exceptional recovery, reliability, and cost efficiency for industrial reuse and ZLD applications.

MAXH2O Desalter: Beating scaling at its own game

The MAXH2O Desalter achieves recovery rates of up to 98%, tackling scaling at the source. Instead of allowing salts to accumulate on membrane surfaces, the system continuously precipitates sparingly soluble salts in a fluidized bed reactor, while recirculating treated water through the RO at high shear velocity.

This unique configuration:

- Prevents scaling and salt buildup

- Reduces biofouling due to dynamic flow conditions

- Accommodates variable feedwater quality

- Lowers CAPEX and OPEX compared to conventional high-recovery RO

A step closer to a waste-free future

With the MAXH2O Desalter and MAXH2O PFRO, IDE is helping industries achieve water recoveries once considered out of reach — cutting waste, reducing freshwater demand, and advancing the shift toward true circularity.

By minimizing thermal dependence and optimizing membrane performance, IDE’s technologies enable industries to move from waste treatment to resource recovery — a vital step toward a waste-free, water-secure future.