Pure, clean water is an essential part of life. We take it for granted that clean water will come out of our taps when we turn them on. Many industries such as food and beverage manufacturing, aquatics, aquaculture, pharmaceutical and horticulture need fresh, clean water to ensure their products are of the highest standard. How can this high standard of pure water be achieved?

Ultraviolet (UV) water purification systems produce disinfected, pure water. No microorganism is known to be immune to UV. Even chlorine-resistant Giardia and Cryptosporidium are deactivated by UV treatment. Economical and efficient, UV water disinfection is chemical-free, with no impact on taste and no corrosion problems.

In UV water disinfection systems, water passes through a reactor in which a single or multiple UV lamp(s) are situated. Any pathogens in the water are then deactivated by the UV energy that penetrates the pathogen’s outer cell membrane, passing through the cell body, disrupting the genetic core (DNA) and eliminating its ability to reproduce. Disinfecting water with UV light is simple, effective and environmentally safe. UV systems are designed to destroy at least 99.99 percent of harmful microorganisms without added chemicals, taste changes or odor. UV treatment does not alter water chemically. Nothing is added except energy, which means it can be used across a range of applications and industries.

Ultra-pure water for pharmaceutical applications

Because of UV’s ability to disinfect ultra-pure water without byproducts or chemicals, it is an ideal option for the pharmaceutical industry, the cosmetic production industry and medical premises that require sterile water. It can be used alone or in combination with other treatment methods, such as reverse osmosis (RO) and electro deionization (EDI) to remove chlorine and ozone.

Wastewater treatment

UV water purification systems are commonly used at wastewater plants because of UV’s ability to deactivate microorganisms such as E. coli, Salmonella, Vibrio, Cryptosporidium, Giardia, enterovirus, hepatitis and Shigella — all dangerous bacteria capable of causing debilitating illnesses. Municipal wastewater plant operators are required to adhere to a certain level of water disinfection, ensuring that specific microorganism limits are achieved before reuse or discharge to surface waters.

UV provides effective water disinfection against all known microorganisms including spores, mold, yeast and protozoa. Overdosing is not a danger because no chemicals are used. UV water disinfection systems deactivate microorganisms at the point of contact, meaning UV can be implemented throughout treatment plants to protect other treatment processes from microbiological colonization.

Aquatic applications

UV water treatment also deactivates bacteria, viruses and molds in swimming pools. It reacts to break down chloramines (also known as combined chlorine that occurs when free chlorine reacts with human perspiration and urine within the swimming pool). Chloramines are responsible for the unpleasant smells in swimming pools and the cause of swimmers’ eye irritation. With UV disinfection, less chlorine is required, so swimmers have a much better experience and filters are backwashed less frequently, resulting in less water use while allowing swimming pool owners to meet strict regulatory requirements.

Case Study 1 – Controlling Legionella with UV

Legionnaires’ disease is a debilitating and potentially fatal condition caused by the Legionella bacteria that thrive in warm, moist environments. Those with lowered immune systems are at higher risk of contracting the disease that can be transmitted through hot and warm water systems, such as those found in aging care facilities and hospitals.

The disease causes flu-like symptoms and may be fatal. In general, the sources of Legionella bacteria in recorded outbreaks have been traced to either large air conditioning units or hot water distribution systems that have been incorrectly commissioned or poorly maintained.1

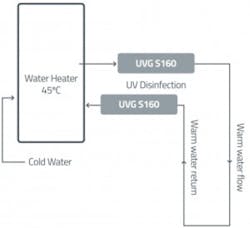

Low levels of Legionella are commonly found in drinking water supplies. However, the bacteria multiply quickly within warm water infrastructure if no disinfection strategies are in place. Thermostatic mixing valves, commonly used in health care and hospitality industries to provide water at a preset temperature, do not provide microbial control and may, in fact, promote the growth of Legionella and other microorganisms. An established and cost-effective way to control Legionella is to install a UV disinfection system on either or both the warm water outlet or return line of the water heater.

A manufacturer of UV disinfection products recently installed a system at an aging care facility in Sydney, Australia, that accommodates up to 78 people. This system’s function was to provide safe, warm water for showers, hand basins and baths. Because warm water systems are circulatory systems, once the Legionella bacteria enter, they will stay within the system until they are removed or controlled.

The UV system specified for this particular application was installed on the outgoing plumbing infrastructure from the warm water tank (see Figure 1). This was the closest point at which the warm water would be used by the occupants, without installing multiple UV units on all points of use.

The manufacturer’s engineers needed to ensure that the UV system specified was fit for the purpose and sufficient for the deactivation and destruction of the bacteria by delivering the correct UV dose. (UV dose equals the UV intensity from the lamp multiplied by contact time [time within the UV reactor]). They needed to establish three key parameters:

Figure 1. Diagram of

the warm water system

UV intensity monitoring was provided on the installed system to ensure that the designed UV dose was achieved at all times. If the designed UV dose was in danger of not being achieved, the UV intensity monitor would send a signal to the controller, and the nursing home’s building management system would be notified, allowing staff to attend to the system and determine the cause of the problem.

Recommendations were also made to undertake regular water sampling and testing for Legionella within the warm water system at a number of key points to further ensure that the warm water was bacteria-free.

Case Study 2 – UV water disinfection for horticulture

Engall’s Nursery, a specialist nursery that has grown fruit and citrus trees since 1976, uses a UV treatment system to disinfect the irrigation water at its four-hectare citrus growing area in Dural, New South Wales. To achieve certification from the Nursery and Garden Industry Association (NGIA), Engall’s Nursery explored its water treatment options and decided that UV disinfection was its preferred choice. Key to the decision was a UV system’s ability to provide treatment inline when compared to alternative chemical solutions that required large storage tanks.

The engineering team worked closely with the nursery owner and the NGIA to design a solution that incorporated the correct level of treatment required and tested the UVT of the irrigation water in its lab to determine the appropriate dosage. Phytophthora and Pythium were the species highlighted as risks to the crop at the site.

The team specified a UV system that exceeded the requirements determined by the NGIA and the nursery owner. It would achieve a UV dose of 100 mJ/cm2 at the end of the lamp life for a peak flow rate of 27 cubic meters per hour where the UVT was 55 percent.

The skid-mounted system consists of four 450-watt, low-pressure UV lamps. Incorporated into the design was a quartz auto-wiping system activated by UV intensity values measured by a UV intensity sensor and monitor. When the UV intensity drops to a predefined level, the wiping system will initiate and clean the quartz, maintaining the designed UV dose.

The system is controlled by an existing irrigation controller at the nursery. This means that the system is turned on and off only when required, which is recommended to prolong UV lamp life while reducing power consumption.

Reference

- "NSW Code of Practice for the Control of Legionnaires’ Disease." From http://www.health.nsw.gov.au/environment/Publications/legionnaires-disease.pdf

Luke Chamberlain is technical director for UV-Guard. UV-Guard designs, manufactures and supplies water purification equipment and specializes in UV water disinfection. For more information, visit uvguard.com.