For many years, Zero Liquid Discharge (ZLD), a water treatment method aimed at minimizing liquid waste discharge by maximizing water recovery and leaving behind only solid waste, was considered a luxury solution in the world of industrial water treatment. It required substantial investments in advanced equipment, skilled personnel and complex infrastructure, making it a viable option primarily for large corporations with significant financial resources.

However, times have changed, and the landscape of ZLD adoption is poised to look very different in 2024 and beyond.

A brief history of ZLD water treatment

The concept of ZLD has been around for many years, with the first industrial-scale ZLD plant being built in the late 1960s. Most manufacturing plants that used water in their manufacturing processes had to comply with certain parameters for disposing of different contaminants. In order to adhere to these regulations, manufacturers implemented water treatment processes that treated water up to a level that aligned with the regulatory requirement and allowed it to be disposed of to either the sea or a surface water source.

Over the years, many manufacturers who began to experience the high cost of water decided not only to treat the water before disposal but also to reuse some of the treated water in their manufacturing processes. However, whether wastewater was treated for disposal or reuse, most companies treated the water only to a limited extent.

The high cost of ZLD water treatment

The reason most manufacturers shied away from ZLD water treatment was due to its high cost. How high? Well, imagine you have 100 tons of water. Treating and recovering 90% of this water will cost you X. But if you wish to recover an additional 9%, the cost of this process (also known as ZLD) will be double what it took to treat the first 90%. This is why most companies choose to refrain from implementing ZLD processes and opted for an MLD (Mini Liquid Discharge) process.

ZLD’s coming of age

In recent years, new parameters for discharge were introduced by the EPA (Environmental Protection Agency). The driving force behind these new parameters is the discovery of new contaminants identified in the environment.

One such contaminant that has captured headlines is PFAS (Per- and Polyfluoroalkyl Substances). PFAS are a group of synthetic chemicals that have gained widespread attention and concern due to their persistence in the environment and potential health risks. PFAS are characterized by their unique chemical structure, which includes multiple fluorine atoms attached to a carbon backbone. This structure makes PFAS highly resistant to heat, water and oil, leading to their use in various industrial and consumer products.

Certain industries, primarily semiconductors, plastics and chemicals, were identified as industries that release PFAS into the environment and water streams. Regulatory bodies quickly responded, demanding that companies address PFAS contamination. Given that treating PFAS is challenging and expensive, many companies have decided to get ahead of these escalating regulations and invest more money by implementing ZLD processes in their operations.

At IDE, we are already feeling these winds of change as more and more inquiries we receive involve ZLD.

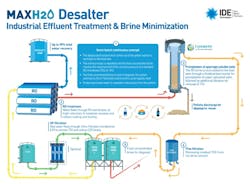

Optimizing ZLD implementation with advanced DESALTER technology

ZLD is not a standalone process. It is part of a multi-stage process that starts with various pre-treatment technologies, continues with membrane treatment, and ends with evaporators and crystallizers. But since the last phase (crystallization) is extremely expensive, the idea is to arrive at this stage after maximizing results from all other water treatment technologies.

The most cost-effective method forminimizing brine volume involves increasing the workload on the reverse osmosis phase and optimizing its recovery potential. This strategy, in turn, reduces the required size of the thermal crystallization unit. However, two primary factors limit the achievable recovery rate of any RO system:

- Operating pressure — reverse osmosis membrane technology has an operating pressure limit which is around 80 bars. The required working pressure is defined by the salinity of the water, which in turn, defines the osmotic pressure of the solution. The higher the salinity, the higher osmotic pressure, the higher is the working pressure. Therefore, at a certain salinity — there is no more room for membrane treatment and the water needs to be treated by evaporators.

- Scaling and fouling — the chemical composition of the feed water defines the ability to treat the water within a reverse osmosis membrane without scaling or fouling on the membranes. If the water analysis is of bad quality, the ability to treat it with reverse osmosis membranes is limited because it will get clogged quickly.

It is our goal to recover as much water as possible and try to reach the highest salinity in the brine coming out of the reverse osmosis system, hence reach as close as possible to the maximum allowed operating pressure. However, due to scaling and fouling challenges, most of the time it is not possible and the water is sent to the thermal crystallization process at relatively low salinity and in large volumes before the reverse osmosis technology was able to recover water to its maximum operating pressure capability.

In response to this challenge, IDE has developed a process that overcomes these limitations and supports brine minimization: the MAXH2O DESALTER.

The MAXH2O Desalter is an advanced reverse osmosis (RO) solution, featuring an integrated salt precipitation cycle designed for high-recovery applications. This innovative process not only maximizes the water treatment capabilities of RO but also effectively addresses the persistent issues of membrane scaling and fouling. Remarkably, it achieves the highest recovery rates within the industry and allows the system to work up to the operating pressure limit, hence minimizing dramatically the crystallizer portion of the system. This, in turn, reduces the costs significantly.

ZLD water treatment — what’s next?

In the very near future, many companies will need to accept ZLD as a necessary solution. As the environmental landscape evolves and regulatory standards become more stringent, implementing this advanced water treatment method might come with certain challenges and complexities, including cost considerations, operational complexity and resource allocation. However, while ZLD may pose certain challenges, it also offers significant benefits. It aims to minimize liquid waste discharge, recover valuable resources and reduce environmental impact. It can lead to long-term cost savings, improved regulatory compliance and enhanced sustainability credentials. Companies that embrace ZLD as a proactive and responsible choice for water management are likely to find that the benefits outweigh the initial challenges.

Roi Zaken Porat is a process engineer, team leader and R&D manager that has joined IDE Technologies in 2010. Roi has gained significant expertise in the field of RO and thermal desalination, nano-filtration and industrial wastewater management, and specializes in Zero Liquid Discharge solutions (ZLD), being actively involved with some of IDE’s largest water treatment projects. Graduate of the Technion (Israel’s Institute of Technology), Roi holds a B.Sc. in Biochemical Engineering and an MBA from Tel Aviv University.