The power industry is widely recognized as one of the most water-intensive sectors globally. However, considering water scarcity, stricter regulations and the rising costs of effluent discharge and make-up water, power plants are compelled to optimize their net water consumption efficiently.

Among the various water consumers in a power plant, cooling towers play a significant role and are also responsible for generating the majority of wastewater known as cooling tower blowdown (CTBD).

To address this, an innovative membrane-based technology with high recovery capabilities was developed. It enables power plants to achieve remarkable recovery rates of CTBD, significantly reducing the operational expenditure associated with cooling towers.

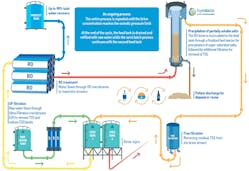

This technology incorporates a single-stage reverse osmosis (RO) system integrated with a salt precipitation unit. The process involves circulating CTBD through an RO system and subsequently passing it through a fluidized bed reactor where controlled precipitation of supersaturated sparingly soluble salts takes place.

This case study presents the outcomes of a 48m3/day MAXH2O Desalter demonstration unit conducted at a power plant in Chile. The unit operated continuously for 30 days and achieved an impressive 96% recovery of CTBD.

With conventional technologies, membrane scaling would have limited the recovery to approximately 55%-60%. However, the achievement of 96% recovery under the mentioned conditions demonstrates a viable and revolutionary solution that can significantly impact the costs and operation of cooling towers in power plants, as well as the industry as a whole.

Overview: Power plant CTBD in Chile

The power plant is a gas-fired power station comprising two combined cycle units, in operation since 1998 (Unit 1) and 2008 (Unit 2), respectively. Each unit is equipped with a wet cooling tower (WCT) for condenser water cooling and its total nominal power output is ~750MW. The plant is located in the Valparaiso region in Chile, which is a water-stressed area where the available water is decreasing.

Water shortages in recent years have affected the CT operation due to increased concentration of salts in the make-up water sources, resulting in a challenge in complying with the blowdown discharge regulations (D.S. Nº 90). The main limiting parameters are the sulphates (≤1000 ppm) and the chlorides (≤400 ppm).

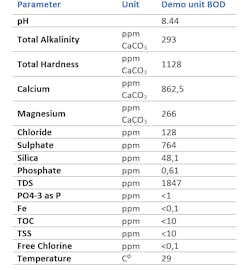

Currently, the source of CT make-up water is from relatively high-salinity brackish wells, which is not as common as CT make-up water (therefore it is sometimes integrated with better quality water from external sources). This fact limits the operational efficiency of the CT in two aspects: (1) low cycle of concentration (CoC) according to the regulatory restrictions; (2) low CoC limited by the water chemistry (scaling and corrosion potential increases). The operated CoC in the power plant is currently ~2. Consequently, the required quantity of make-up water to the cooling towers is high, as is the blowdown discharge. The current CTBD water quality is presented in Table 1.

The core process — MAXH2O desalter

The newly developed technology that enables overcoming the above challenge comprises a single-stage RO system with an integrated salt precipitation unit, making it possible to treat the blowdown stream and, in the current case, to reuse this as a make-up in the cooling towers (generally, there are additional options such as discharge to the environment, disposal, etc.).

The unit operates by recirculating pre-treated water through the RO system at high shear velocity and continuously precipitating supersaturated salts from the recirculated brine. This significantly reduces the salt concentration build-up near the wall of the RO membrane, minimizes the negative effect of concentration polarization and prevents the precipitation of sparingly soluble salts and biofouling on the membranes. The salt precipitation unit downstream reduces the saturation of sparingly soluble salts in the recirculated brine. This allows continuous cycles through the RO system until it reaches maximum brine osmotic pressure.

Water quality and chemistry

The CTBD stream today is less concentrated than the future stream will be, according to design and calculations. Once the blowdown is treated in a zero liquid discharge (ZLD) process, no discharge regulations limit the CoC, and together with better quality make-up water, the CoC of the CT can be increased up to the chemistry limits (scaling or/and fouling in the CT).

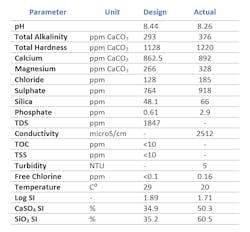

The water quality today compared to the basis of design (BOD) quality are presented in Table 2.

The actual water quality on site is a little more concentrated than that designed for the demonstration unit except sulphate and silica that is higher by 20% and 37%, respectively, more than the "design" quality. The major aspect that this might affect is the chemical consumption of the process, as well as the consumption and discharged amounts of pellets in the precipitation unit.

According to the BOD water quality, a conventional RO process would be limited to ~50% recovery (considering antiscalant) due to chemical scale, where the first to appear is CaCO3 (LogSI ~2.25). Compared to this, the new technology can reach 96%-97% recovery, with theoretical saturation indices reaching LogSI ~3.2, CaSO4 SI ~2290%, and SiO2 SI ~1475% (practically, precipitation occurs proactively in small steps along the cycle as the water recirculates and concentrates).

Results and discussion

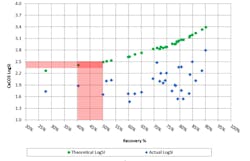

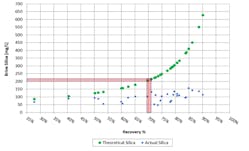

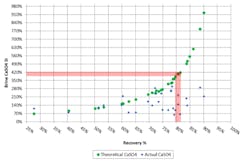

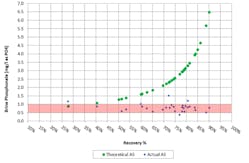

This section presents three weeks of continuous operation of the demonstration unit (after three weeks of commissioning) with the actual CTBD water quality (see Table 2). The system recovery increased gradually along this period. This article was written during the operation period and the recovery rate will continue to rise in the upcoming month until the target value of 96% will be reached. Figures 2, 3, 4 and 5 present the sparingly soluble salts removal along the recovery increase up to 91% while the operating pH ranged between 8.9-9.2. RO feed pressure, at the end of the longest cycle, was only 25–27 bar, meaning that a further increase in recovery is possible until the osmotic pressure is being a limitation.

In Figure 2 it can be seen that the Actual CaCO3 LogSI stabilized in the range of 1.6-2.3 (differences may be related to temperature differences between daytime and nighttime, operated pH while samples were taken, residual antiscalant concentration, etc.) while the theoretical value reached 3.4. Theoretical values are calculated as if no CaCO3 precipitated in the system and the calcium and alkalinity levels in the brine concentrated according to the system recovery. Actual values are the actual sampling results as tested from the final brine. Standard RO process would be limited to 40%-50% recovery. It is limited due to CaCO3 supersaturation that exceeds the antiscalant capability to prevent scaling. The difference between the theoretical to the actual value stands for the CaCO3 precipitation in the crystalactor.

Figure 3 shows that the residual silica concentration in the brine was stabilized in the range of 100-150 mg/l, compared with the theoretical value of 630 mg/l. A standard RO process would be limited to ~70% recovery due to a silica saturation limit with antiscalant. The delta in concentrations precipitated in the crystalactor.

Figure 4 shows that the CaSO4 SI in the brine was stabilized in the range of 250-280%, compared with Theoretical value of 920%. Standard RO process would be limited to ~80% recovery due to the antiscalant limitation of ~ 400% saturation.

Figure 5 shows both phosphate and magnesium removal in the crystalactor. Phosphate concentration was stabilized at ~ 0.75 mg/l and Magnesium at ~320 mg/l.

Figure 6 emphasize the core mechanism of the crystalactor: The antiscalant is dosed continuously along the process, it protects the membranes from scaling and is then deactivated in the crystalactor so that the supersaturated salts can precipitate without the interference of the antiscalant agent, and thereafter, the saturation levels decreased until the next circulation. Residual concentration has been optimized and stabilized at ~0.75 mg/l.

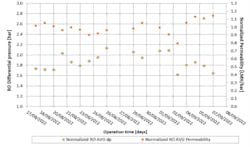

Figure 7 shows the system's normalized differential pressure and permeability that fluctuate in a reasonable narrow range: the permeability drops at the end of August (and system differential pressure increase respectively) caused by a few hours of system shutdown without flushing (static supersaturated water inside the membranes), that was followed by acidic flushing that reset the parameters to their initial values.

Conclusions

The new technology was successfully tested with CTBD water that was enriched with hardness, silica and sulphates. The results show that the system can reach recovery of over 91%, where typical RO would lead to immediate calcium carbonate, silica, calcium sulphate and phosphate precipitation on the RO membrane. In practice, the calcium carbonate LogSI, silica concentration and calcium sulphate saturation index were maintained below or equal to antiscalant limits by its continuous precipitation in the crystalactor, the integrated salt precipitation unit. The produced pellets drained gravitationally and reached more than 95% dry solids content, which do not require further sludge dewatering treatment. Depending on the client's needs, effluent requirements and regulations, the obtained RO brine stream can be partially or completely blended with the RO product for discharge or can continue to a further crystallization stage in a full ZLD process. Any of these options will improve the cooling tower operation efficiency in terms of higher CoC and reduced water consumption.

These results show the significant advantage of the developed process as a treatment alternative for a CTBD stream. The developed process saves operational costs by decreasing the amount of sludge to be discharged and by minimizing the energy intensive tail crystallization stage. Capital costs savings can be embodied in the redundant multi-softening and RO stages, sludge handling units and/or bigger crystallizers.

Roi Zaken Porat is the director of water treatment process at IDE Technologies.