Cooling Water Treatment Using Controlled Hydrodynamic Cavitation

By Philip Vella

Treating cooling tower water to prevent biological fouling, scale, and corrosion is a complex, highly monitored process. Most cooling tower treatment in the U.S. is accomplished with biocidal, dispersant, and scale-inhibiting chemicals. While chemical treatment is effective, there are considerations beyond the cooling tower. Regulations are increasingly stringent for chemical storage, handling, and disposal. Reducing or eliminating chemical usage in the treatment of cooling-tower water is the ultimate objective.

To resolve many of the issues associated with chemical treatment, technologies using non-chemical treatment have been evolving. Non-chemical devices (NCDs) use many different technologies to achieve biological and corrosion control. Over 30 suppliers are known to provide commercially available products that can be grouped into four basic classes or methodologies: magnetic devices; induced electric field devices; ultrasonic devices, and mechanical energy devices.

VRTX™ Technologies, a Schertz, Texas-based fluid technology company, specializes in environmentally friendly chemical-free treatment of water used in cooling towers and evaporative condensers. Its technology would be considered a mechanical energy device. The VRTX system relies on kinetic energy through Controlled Hydrodynamic Cavitation (CHC) in addition to chemical equilibrium to control scale, corrosion, and bio-fouling without the hazards of chemical treatment. CHC also minimizes corrosion and microbiological growth, reduces system operating costs, and conserves water and energy.

Figure 2: A typical CHC unit with side-stream filtration. Left (front).

How CHC Works

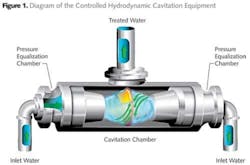

The CHC unit consists of a pressure equalizing chamber and a cavitation chamber as shown in Figure 1. Inside the cavitation chamber, two pairs of nozzles are positioned opposite each other at specific distances, lengths, and angles. Water is first pumped into the pressure equalizing chamber at a pump pressure of ~70 PSI. From the equalizing chamber, water is channeled into the cavitation chamber, where water is forced to rotate with high velocities. The rotation of water streams creates a high vacuum, typically greater than -30 inch Hg. This high vacuum condition causes micro-sized bubbles to form in the water streams. These bubbles are filled with a mixture of vapor and dissolved gases. The water streams in two nozzles rotate in opposite directions. Meanwhile, the water streams travel forward at accelerating speeds. Upon exiting from the nozzle, the opposite water streams collide at the mid-point of the cavitation chamber as shown in Figure 1. At this point, pressure increases spontaneously, causing the sudden implosion of micro-sized bubbles. At the moment of collapse, hydrodynamic cavitation generates intensive shocking waves and produces extremely high temperatures. Under these conditions, chemical reactions such as conversion of dissolved calcium and bicarbonate ions into calcium carbonate (CaCO3) and oxidation of organic compounds can occur. In addition, the bacteria in the water are ruptured by mechanical, physical and chemical forces.

Suspended matter is removed from the cooling tower sump via the second "side stream" loop that is designed to sweep the debris from the floor of the sump into the automatic filtration and collection system. The filter is automatically backwashed to remove solid matter on a timed basis and is sent to waste.

Case Study

An Orange Juice Processor located in Florida has a state-of-the-art facility designed to keep citrus and juice products refrigerated. The facility's North Condenser System (NCS) has the capacity to handle 15,000 tons of ammonia refrigeration. It is one of the largest refrigeration systems in North America.

The NCS is an essential component of the ammonia refrigeration system that is responsible for keeping the perishable products at the facility frozen. The facility identified the NCS for evaluating the CHC technology. The condenser system consists of a bank of 18 new evaporative condensers (ECs) with a combined 15,000 ton cooling capacity.

The water treatment committee at the facility managed the CHC project. This committee began its task by seeking the best available technology and then establishing the goals, objective and performance measurements. The emphasis was on operational efficiency, environmental compliance, water conservation, and improved worker safety.

The facility purchased and installed three 250 gpm CHC systems to the sump basin water that serves the NCS. Due to the size of the system a separate automated filtration system was installed on the main condenser basin to separate and remove precipitated solids from the condenser water stream. The CHC system ran under the same load and conditions as the previous chemical programs used prior to CHC installation. The makeup water for all systems was the same and prior to final startup the evaporative condenser system watersides were passivated, as per manufacturer specifications.

Throughout the one-year evaluation period, the committee used independent lab data as well as CHC lab data to measure performance.

Results

Since startup over seven years ago, the CHC system has yielded significant water savings, along with the option to reuse large quantities of non-potable water. Corrosion control was below Cooling Tower Institute (CTI) standards. There was little or no scale buildup on the critical heat exchange surfaces, and the CHC system was able to control microbiological activity below CTI specifications. Details of the system's performance are given below.

Corrosion

The results for corrosion coupon testing are contained in Figure 3. No pitting was noticed on any test coupon. On galvanized steel, the corrosion rates were good to excellent for passivated and non-passivated galvanized coupons.

Scale Buildup

No significant scale buildup was observed in the systems. Frequent visual inspections, Delta Ts, and ammonia head pressures concluded that no measurable heat transfer efficiency loss occurred since the CHC technology has been treating the NCS.

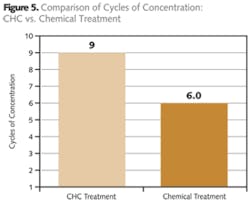

It should be noted that the makeup water at the facility is reasonably aggressive. Nevertheless, the CHC system was able to operate, on average, at cycles of concentration above 8.5 without any scale buildup. This is compared and contrasted to chemical treatment systems operating at 5.9 cycles of concentration.

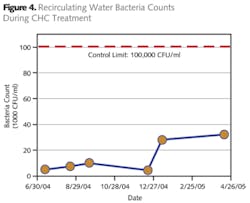

Microbiological Control

Microbiological counts averaged less than 350 RLUs or approximately 10,000 CFU/mL for this system. No significant bacteria slime was noted on the evaporative condenser coils.

Environmental Impact

Figure 5 summarizes meaningful and significant water conservation. As noted, annual water savings are over 5.4 million gallons of water. Moreover, the use of the CHC system has allowed over 7 million gallons of non-potable water to be available for reuse on an annual basis.

About the Author: As technical director for VRTX Technologies, Philip Vella, PhD, directs all experiments and laboratory work pertaining to potential applications for controlled hydrodynamic cavitation. He holds a doctorate in inorganic chemistry from University at Albany, State University of New York. He can be contacted at [email protected].

Past IWW Issues