Study: Animal Processing Wastewater is One of Largest Water Treatment Markets

There are more cattle, hogs and chickens in the United States than there are people. Just the first two account for 100 million and 60 million, respectively. And of the 10 billion animals slaughtered for food in the United States each year (excluding fish and other aquatic life), over 8.9 billion are “broiler” chickens.

It takes a lot of water to process those animals into ready-to-eat products. And that water has to be treated before being discharged afterward. The huge investment in wastewater treatment plants for households is indicative of the potential as the animal processing industry comes to grips with its pollution problems. A rejection in late February by a federal appeals court of an attempt to exempt livestock operations from aspects of the Clean Water Act only accentuates that potential.

When you add in all the other 85,000 industrial plants which have wastewater discharges, the large size of the industrial market is readily apparent. Increased regulatory scrutiny has created a big market for treatment of wastewater being discharged directly to receiving streams rather than to municipal treatment plants by more than 90,000 U.S. facilities.

These facilities in general have large enough flows to justify the investment in treatment equipment rather than pay municipalities for this service. The McIlvaine Company, of Northfield, Ill., has compiled rankings of these facilities by number within each industry category and included this display in an online database: “U.S. Industrial Facilities with Water Discharges.”

The heavy construction industry heads the list with just under 4,000 facilities. This does not include 2,000 ready mixed concrete plants and another 1,800 crushed and broken limestone plants. It does not include 1,700 sand and gravel plants. 1,854 power plants are direct dischargers. But this is equaled by the number of gold mines. 1,200 bituminous and lignite coal operations are also included.

The food and related industries are significant dischargers (see Table 1) as well. These facilities are subject to existing and proposed discharge rules.

For instance, the EPA will have to re-evaluate its farm pollution laws after a federal appeals court in New York struck down water regulations considered too lenient toward the livestock industry (see: “Court Rejects Bush Factory Farm Rule,” Environmental News Service: www.ens-newswire.com/ ens/ mar2005/ 2005-03-01-10.asp)

And on June 30, the EPA finalized a rule to reduce discharges from farm-raised fish facilities that generate wastewater and discharge it directly into U.S. waters. The rule will reduce annual discharges of suspended solids by more than 500,000 pounds, and also will reduce the amount of toxic pollutants at 245 facilities that produce at least 100,000 pounds of fish per year and discharge at least 30 days per year.

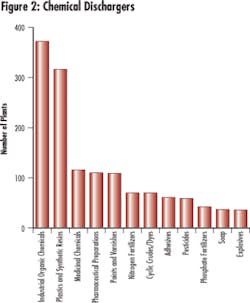

The chemical industry is another segment with large numbers of direct dischargers (see Table 2).

The 90,000 plants include many commercial facilities such as hotels and retail operations. There are also 2,400 gasoline service stations and 1,600 crude oil and gas operations in the database.

The database is organized for easy access by geographical location, industry category, or plant name. Contact names and phone numbers are included. A companion database, U.S. Industrial Analyses, has the State-by-State segmentation. For more information on the report, see “U.S. Industrial Facilities with Water Discharges” at www. mcilvainecompany.com/water.html#61EI.

Additional information on federal animal feed lot rules can be found at the EPA website: www.epa.gov/agriculture/anafoidx.html.