High-Efficiency Reverse Osmosis Treats Gray Water for Power Generation

By Khaled Moftah and Patrick Randall

The Bajio Power Project, a 600 MW combined cycle project located in San Luis De La Paz, Mexico, is in an arid area with limited water resources. Ground water is not permitted for industrial and power generation purposes. The only supply for boiler feed was silica-laden secondary treated sewage gray water. Because of limited supply and discharge restrictions, a high-recovery reliable solution was required. The solution was a treatment plant designed, built and commissioned by Aquatech International Corp. to produce demineralized water for the plant.

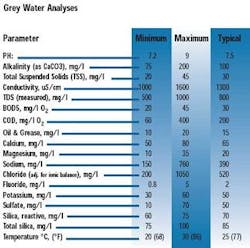

The design of any water treatment system is dependent on the feed water and product water characteristics. Secondary treated gray water has wide swings in quality, which must be considered for the success of any design.

The feed water had high levels of many difficult-to-treat contaminants, and the water treatment system was required to provide at 75 – 80% recovery. Typical values are: silica, 85 ppm; BOD, 30 ppm; COD, 200 ppm; TSS, 30; TDS, 1300 ppm; and oil and grease, 15 ppm.

Effective treatment of gray water is not a new concept — but doing it effectively at high recovery with limited cleaning and downtime of the RO system in the presence of 85 ppm silica until recently was believed to be unachievable.

RO System

The High-Efficiency Reverse Osmosis (HERO™) system selected is simply a combination of four processes; hardness removal, alkalinity removal, decarbonation, and high recovery reverse osmosis under high pH conditions. This integration of equipment aims at high recovery of the reverse osmosis, eliminating scaling and fouling in the RO unit while at the same time improving the permeate quality. The process combines the use of ion exchange and decarbonation for hardness, alkalinity, and carbon dioxide removal as a pretreatment, which permits high recovery and high silica rejection at the reverse osmosis proper.

The reverse osmosis unit operates at pH >10, which is favorable for silica solubility without fear of silica or hardness scaling. Hardness had been removed in the pretreatment ion exchange. Operational pH is selected such that silica levels in the reject are soluble. This high pH operation also emulsifies or sapponifies any oil or grease thus alleviating RO fouling due to their presence. In addition there is no biological fouling because of the operation at high pH. This is in contrast to conventional RO which operates at acidic or near neutral pH, susceptible to silica scaling, organic and biofouling. This design also achieves high recovery with minimal waste water emanating from the system.

Project Design

The Bajio water treatment system is composed of a pretreatment section and a demineralization section. The pretreatment consists of clarification and two-stage filtration. More specifically, it consists of a gray water receiving sump and pump facility, a solids contact clarifier, gravity dual media filter, clear well and pressure filter feed pumps, pressure dual media filters, filtered water tank, backwash pumps and air scour blower. The pretreatment also includes the sludge handling facilities comprising sludge transfer air diaphragm pumps, sludge thickener and plate and frame filter press. In addition, various chemical dosing systems like sodium hypochlorite, caustic, coagulant (FeCl3), coagulant aid, thickener aid and carbon dioxide also form part of the pretreatment section.

The demineralization section comprises filtered water pumps, weak acid cation exchanger units, a decarbonator tower with a catch tank, RO feed pumps, cartridge filters, RO booster pumps, RO units, a permeate tank, mixed bed feed pumps and mixed bed exchanger units. A unique reject stream inclined plate clarifier is used for silica-laden sludge thickening. The sludge is then dewatered in a filter press.

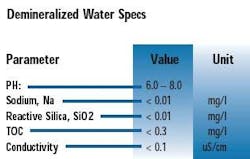

The WAC outlet water will have excess alkalinity not associated with hardness in bicarbonate form. This excess alkalinity is converted to carbonic acid by addition of hydrochloric acid online before taking it to the decarbonator to remove excess alkalinity in the form of free carbon dioxide. Caustic is injected after the decarbonator ahead of the reverse osmosis units and is calculated based on hardness, alkalinity, silica, temperature, and TDS of the RO feed plus the recovery value, which determines the concentration of chemical species in the reject. The permeate (product) from the RO units is further polished in a mixed bed ion exchange to obtain the desired boiler feed water quality.

RO Optimization

A key to a successful operation of the whole system is the proper operation of the WAC. Hardness leakage needs to be kept to minimum. The Langelier Saturation Index (LSI) in the RO is a controlling factor. This LSI needs to be kept negative. The LSI is calculated from the equation:

LSI = pH - log (Alkalinity) - log (Calcium Hardness) - C

Where alkalinity and calcium hardness are in mol/l as Calcium carbonate. C is a weak function of the TDS and ranges between 2.3 and 2.4 at 20°C for TDS 1000 to 10,000, and there is not much that operators can do about it. They don't increase the TDS in order to increase C and obtain a favorably negative LSI.

In order to keep negative LSI they seek:

- Operation at a lower pH. That is why in conventional RO, acidification of the RO feed may be performed. This cannot be done in the Bajio case. The operational pH is determined by the silica level. The system needs to keep the high silica in the reject soluble and this can be done only at high pH.

- Decrease the calcium hardness or alkalinity or both to as low levels as possible. That means keeping the hardness leakage from the pretreatment ahead of the RO (WAC in the selected design) as low as possible.

- Decarbonate the water at acidic pH in order to remove CO2, which is converted back to alkalinity at the high pH operation.

System Performance

The RO recovery is 85% and the overall system recovery is 78.5%, which meets the target value.

About the Authors: Khaled Moftah is Senior Chemical Engineer with Aquatech International Corp., Canonsburg, PA (Phone: 724-746-5300; E-mail [email protected]) Moftah has over 25 years of experience in chemical industries and water treatment fields. He holds M.A.Sc. from the University of Toronto, Canada. Patrick Randall is Regional Sales Manager with Aquatech International Corp., Tampa, FL. Randall has 17 years of experience in the mechanical engineering field, the last seven specifically in the water treatment industry. He holds A.A.S. in Mechanical Engineering from the State University of New York and A.A. in Business from St. Petersburg Junior College in Florida.