Saving water and tailings dam space: Part 2 — pilot results, optimization and long-term potential

Key Highlights

- The pilot trial successfully demonstrated the centrifuge's ability to meet water recovery and tailings reduction targets in a challenging mining environment.

- Operational stability was maintained through automatic adjustments and continuous monitoring, even under variable feed conditions and tramp material challenges.

- Results support scaling up to larger centrifuges, with potential for significant environmental benefits and operational cost savings in mining operations.

By Eric Gentis, Stephen Benyo, Guillermo Flores, Gabriel Rodrigues and Dustin Miller of Flottweg Separation Technology

Part 1 of this series outlined the operational challenges facing a medium-sized fluorspar mine in central Mexico and described the setup of a month-long pilot trial using a Flottweg mining decanter centrifuge. In this second and final installment, we present the trial’s findings in detail, including separation performance metrics, optimization strategies and operational insights. Readers will gain a deeper understanding of how the technology performed under real-world mining conditions, and what these results mean for scaling up water recovery and reducing tailings dam dependence.

Following the month-long pilot trial setup described in Part 1, the mining team and Flottweg engineers began full 24/7 operation of the Z5E mining decanter centrifuge.

With the feed challenges addressed and the unit running steadily, the focus shifted to collecting and analyzing performance data under a variety of operating conditions. The goal was to determine not only whether the centrifuge could meet the mine’s water recovery and tailings reduction targets, but also how to optimize its operation for efficiency, reliability and scalability.

Purpose of the pilot trial

The main objectives for the mining company included:

- Reduction of water consumption for significant Opex cost savings, as well as for the sustainable use of resources.

- Minimizing the daily volume of tailings to the current dam, which will increase its lifetime by more than 5x. This will further improve the efficiency of their tailings management system by returning water to the process.

- Minimizing environmental impact of the tailings operation and reducing the tailings footprint on local rural land.

- Use of any polymer or coagulant is not permitted as it negatively impacts the flotation process. Separation must therefore be done mechanically only.

- To pilot test the Z5E unit on site to ensure the possibility of scale-up to the Z92s as currently installed at their original mine and plant site.

Pilot trial

The pilot unit was brought up to optimal operating performance relatively quickly once the initial feed issues were overcome. These issues were:

- Settling of the larger sand particles in the longer-than-usual feed line which choked the feed capacity down; and

- Larger tramp mineral pieces (often more than 6mm, some as large as 10mm) causing the lobe feed pump to occasionally operate sub-optimally.

The opportunity to test various scenarios using differing feed rates and centrifuge bowl and scroll speeds was taken. This was done to ascertain whether various optimum feed/differential speed combinations between centrifuge bowl and scroll RPMs could successfully be achieved. Clarity of the resultant centrate (liquid discharge) and dryness of solids (DS) produced was measured against the input feed at each setting.

The trial proved that the mining centrifuge can be rapidly recalibrated, allowing the running of multiple separate “what-if” scenarios over the trial period.

The Z5E unit is still operated 24/7 at the time of this writing and the same sampling protocol is continued approximately every hour. The 117 data points selected represent both planned variables tests and mimicked “steady state” operation.

Methodology

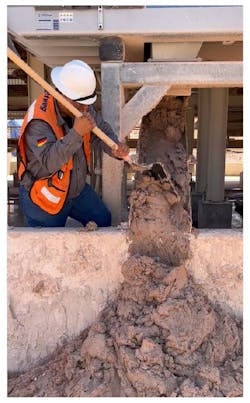

The Flottweg model Z5E-4/451 decanter centrifuge selected was equipped with a unique mining-state wear package to ensure that wear on the bowl, scroll and all entrance and exit points of the unit are protected against the sliding wear that accompanies the typical mining material found in mining process underflow. It is designed with the durability to cope with occasional tramp materials typically found in a mining environment.

The pilot test equipment consisted of the decanter centrifuge, its steel elevation stand and its sealed/cooled control panel. It also included a feed pump and flowmeter. This unit did not have a density meter, so readings were mostly set at 15% solids for calculation purposes.

The centrifuge discharges both the solid and liquid streams by gravity.

The centrifuge’s control panel is connected to all instrumentation and monitors all aspects of operation. Immediate and automatic adjustments are made to account for changes in volume or density input feed. The master controls will select any needed changes in RPM of bowl and/or scroll, also their differential speed to maintain steady-state output. Bearings are also continuously and automatically monitored for any vibration changes, as is electrical feed.

Any loss of power will have the centrifuge automatically cut input feed and drain the bowl of solids. Resumption of power at any time will have the unit automatically come back to steady production state, no matter which part of the powering-off cycle is interrupted.

Analysis

A field lab was set up at each site to analyze dry solids (DS) for the feed, centrate and cake samples generated. Duplicate samples were also taken for analysis at the Flottweg laboratories, which conducted additional analysis including total suspended solids (TSS) of feed and centrate samples. Multiple samples of feed, solids and centrate were sent to Flottweg’s U.S. and Germany laboratories for analysis.

Quality of separation

The quality of separation is evaluated by the suspended solids recovery, the percent of total solids in the dewatered cake and the polymer consumption. Adjusting operating parameters determine the quality of these criteria.

The quality of the solids recovery can be evaluated visually. This rapid feedback allows for optimization to focus on generating the driest possible solids with acceptable centrate.

Centrate clarity produced by the centrifuge

The following is the particle size distribution data of the remaining suspended solids in the centrate is below. It shows a range from Dv50 at just under 0.64µm; Dv80 at around 1.37µm; and Dv90 at 1.37µm — very fine particles.

Later review of the centrate quality indicated the presence of dissolved solids in the centrate. This implied that the centrate has approximately 0.5% to 0.6% more solids than indicated graphically below. This type of additional dissolved solid must be allowed for when making final decisions.

Results

Several comparisons were made using the data collected. In some instances, a multiplier has been added to one set of numbers to be able to meaningfully compare these with base numbers of another set of data.

Most variation of g-force was trialed in the initial 50 samples. Interestingly, even if the bowl RPM of the centrifuge were either increased or be reduced meaningfully (say by as much as 20% either way), we can expect that the dryness of the solid cake will not be impacted significantly. This is important as it permits using the larger centrifuges at lower RPMs where RPM limitations are dictated by physics affecting spinning very large tonnages.

Again, most variation of g-force was trialed in the initial 50 samples. Not much correlation appeared when creating the variable g-forces. Then, when the bowl RPM of the centrifuge was maintained constant during the second half of the pilot, the clarity of the centrate was still averaging at 0.6% and well under 1% suspended solid. This is important as it permits using the larger centrifuges at lower RPMs where RPM limitations are dictated by physics affecting spinning very large tonnages.

In this example, a reasonable correlation was found between the feed rate supplying the centrifuge, and the resulting solids content found in the produced centrate. Due to the fast-settling nature of the feed, the pilot testing experienced a consistent decrease in feed rate throughout the trials, as the coarse silica settled in the +/- 40m feed line prior to reaching the centrifuge, creating a constricted feed.

Upward spikes found in the feed rate are created when the operators would engage the manual flush line to assist in flushing the feed line of those smaller particulates. As this constriction would limit smaller particles from reaching the centrifuge, these smaller particles were not provided the opportunity to be spun in the centrifuge, where, dependent upon particle size, may have been found in the centrate, leading to a higher % of remaining solids. With this understanding, while measurable, even when the feed rate was fully flushed, the % of solids in the centrate remained consistent at 0.5-1% solids by weight in the centrate.

The centrifuge is equipped with a two-frequency inverter “Simp Drive,” which allows for stepless adjustment of the scroll speed, permitting a fully automatic mode. Utilizing the scroll’s differential RPM as the variable for these tests, with a differential speed range of between 20RPM and 50RPM, it was found that there was no correlation between the differential RPM and the solids remaining in the centrate which indicates a propensity to allow for selection of a Scroll Differential RPM that provides optimal energy utilization.

The differential speed can permit additional settling time in the bowl, for solid/liquid separation, which becomes particularly advantageous in feed containing similar SG material requiring separation.

The differential RPM is utilized as the variable for these series of tests. In this circumstance, we do not see correlation between a higher differential RPM, and the % of dryness of total solids in the cake produced from the centrifuge.

While there are certain portions of this test mirroring correlation in the last 60 tests, the consistencies in a lack of correlation in the first 50 tests confirm additional variables contributing to dryness of solids in the cake, beyond differential speed. Removing outliers from variable testing of other inputs, a consistent dry solids content of +80% was achieved.

Conclusion

This proved to be unique study, as the original intention was not to perform testing but rather to mimic a future full-time installation.

The pilot installation technical team had optimized the equipment to the best possible settings to produce the highest centrate clarity. Hourly monitoring of this steady state then took place to observe the upper and lower limits that the process produced. These proved to be remarkably stable, as can be observed on the graphs.

We used this site also as an opportunity to expand upon this pilot with additional testing of a multiple variables, to observe what factors could influence solids and centrate outcomes. The presence of the onsite laboratory allowed the test team to produce rapid feedback to results.

It was found to be an ideal environment to run a series of “what-if” variables that alternate sites may encounter when implementing centrifuge technology, to further the understanding of the flexibility and efficiency of the centrifuge, regardless of feed or power issues that would otherwise interrupt production.