The importance of industrial water and steam treatment, Part 4.5

A very important part of the discussion in the previous installment of this series1 concerned flow-accelerated corrosion (FAC) and the proper feedwater treatment methods to control it. An integral component of any treatment program should be iron monitoring to ensure that feedwater chemistry is optimized. It seems though that some power plant and design-engineering personnel do not recognize the importance of condensate/feedwater iron monitoring, or they cling to somewhat archaic methods to do so. This article outlines modern methods for iron monitoring.

Times have changed

The large coal-fired plants of the last century were built for base-load operation. Once the unit reached steady-state operation following an outage, the goal for operators and technical personnel was to maintain stable conditions for the long term. Iron monitoring was only considered important at unit startup following an outage. Any shutdown — but especially long outages — will cause impurities and debris, including iron oxide particulates and silica, to dislodge from various surfaces in the steam-generating network and enter the condensate on startup. Common, therefore, was to “hold” the unit at graduated pressure stages to allow impurity removal via the boiler blowdown.

Typically, more than 90% of iron corrosion products in a steam-generating network exist as iron oxide particulates. The Babcock & Wilcox Company developed the Millipore filter test to evaluate feedwater iron concentrations based on the intensity of the color produced on white filter paper, per filtration of one liter water samples. The papers must be dried to perform an accurate analysis, after which the color can be compared to reference charts. These tests can be quite effective for determining when boiler load can be increased during startup. However, more precise analytical techniques to measure iron concentrations in a low part-per-billion (ppb) range are necessary for evaluating FAC, which leads to the core discussion of this article.

Trace iron analyses for FAC control

As outlined in Reference 1 (and in References 2 and 4 of that article), and as the name implies, flow-accelerated corrosion occurs at locations of flow disturbances in feedwater piping such as elbows, reducing fittings and economizer elbows. The elbows in the low-pressure circuits of heat recovery steam generators (HRSGs) are also susceptible to FAC. Because FAC is a localized corrosion mechanism, serious damage can occur with only slight metal loss. Guidelines by such organizations as the Electric Power Research Institute (EPRI) and the International Association for the Properties of Water and Steam (IAPWS) suggest that regardless of the feedwater treatment program, with proper chemistry monitoring and control the iron concentration should remain below 2 ppb. Even a seemingly slight elevation above this level, even 5, 10 or 15 ppb at steady-state conditions, suggests inadequate chemistry control, and that FAC may be underway. To reiterate, FAC-induced failures over the last three decades have killed and injured a number of plant personnel. Two photos of the mechanical results from FAC failures are shown in Figure 1.

Accordingly, it is in the best interest of facility managers to invest in the technology and employee training to properly monitor and control steam generator chemistry. Because carbon steel corrosion products predominantly exist as particulate iron, on-line particle counting and corrosion product sampling have been employed for monitoring. The latter incorporates both filtration and ion exchange to capture particulate and dissolved metals. It is common to collect a sample for a week or so, and then have the filters and ion exchange resin analyzed for deposit quantities. The analyzer has a flow totalizer, which allows for calculation of the average metal concentration over the sampling period.

While these techniques have been successful, other methods have emerged that offer good results at reasonable cost. Dissolved iron is easily analyzed by colorimetric lab methods via spectrophotometry. However, this method does not account for particulate iron. Hach has developed a digestion process that will easily dissolve magnetite (Fe3O4) particulates, and, under more rigorous conditions, α-hematite (Fe2O3) particles, from which total iron values can be measured.

Complete dissolution of particulate magnetite and hematite can be achieved with a 135°C, 30 min closed vessel digestion using 240 µL of combination reagent and 12 mL of sample. The digestion is carried out in a 20-mL glass vial heated in an aluminum block. Upon cooling, the sample can be analyzed with a spectrophotometer and a 1-inch cell. The calibrated range using this procedure is 1-100 ppb with a method detection limit (MDL) of 0.3 ppb.3 The detection limit is well within the range needed to monitor FAC in condensate/feedwater systems.

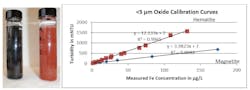

For power-generating units with good chemistry programs, perhaps only a once- or twice-per-week analysis is sufficient to monitor carbon steel corrosion. For large co-generation and industrial plants, continuous monitoring may represent a more proactive approach than grab sampling. Elevated iron concentrations indicate corrosion within the system. Furthermore, the corrosion products will transport to steam generators and deposit on boiler tubes. The insulating effect of these deposits can induce overheating and tube damage. Failure is a common result. Colorimetric total iron analyses can be utilized to calibrate a laser nephelometric analyzer to provide cost effective, real-time corrosion monitoring.

Magnetite and hematite produce a different nephelometric response to visible light. Black magnetite absorbs more and reflects less light than red hematite. Dissolved iron does not give a nephelometric response.

Corrosion products range in size from sub-micron to 10 µm in diameter, with an average diameter of 1 µm. This range of diameters poses another challenge for particle monitoring because nephelometers respond differently to different particle sizes. The numerous variables make it impossible to create a universal nephelometric calibration for quantification of corrosion products. A nephelometric calibration that is appropriate for one process stream will not be accurate for a different system with different corrosion influences. Therefore, quantification of total iron via nephelometry must be accomplished through on-site calibration.3

Conclusion

Condensate/feedwater iron monitoring once seemed to be an issue of minimal concern, at least before FAC announced itself quite dramatically in 1986.4 However, even though much has been written about FAC and its control in the last 30-plus years, many power plant personnel still do not appreciate or perhaps always understand the chemistry that has evolved for FAC control. Iron monitoring should be a part of any program to evaluate and make needed corrections to treatment programs. For co-generation and industrial steam systems, iron monitoring can provide valuable data on the performance of programs to minimize corrosion in condensate-return networks.

References

1. B. Buecker, “The importance of industrial water and steam treatment, Part 4”; Water Technology, Nov/Dec 2023.

2. Buecker, B., and S. Shulder, “Combined Cycle and Co-Generation Water/Steam Chemistry Control”; pre-workshop seminar for the 40th Annual Electric Utility Chemistry Workshop, June 6-8, 2022, Champaign, Illinois.

3. Buecker, B., Kuruc, K., and L. Johnson, “The Integral Benefits of Iron Monitoring for Steam Generation Chemistry Control”; Power Engineering, January 2019.

4. Guidelines for Control of Flow-Accelerated Corrosion in Fossil and Combined Cycle Power Plants, EPRI Technical Report 3002011569, the Electric Power Research Institute, Palo Alto, California, 2017. This document is available to the industry as a free report because FAC is a critically important safety issue.

Brad Buecker is president of Buecker & Associates, LLC, consulting and technical writing/marketing. Most recently he served as Senior Technical Publicist with ChemTreat, Inc. He has over four decades of experience in or supporting the power industry, much of it in steam generation chemistry, water treatment, air quality control, and results engineering positions with City Water, Light & Power (Springfield, Illinois) and Kansas City Power & Light Company’s (now Evergy) La Cygne, Kansas station. His work also included eleven years with two engineering firms, Burns & McDonnell and Kiewit, and he spent two years as acting water/wastewater supervisor at a chemical plant. Buecker has a B.S. in chemistry from Iowa State University with additional course work in fluid mechanics, energy and materials balances, and advanced inorganic chemistry. He has authored or co-authored over 250 articles for various technical trade magazines, and has written three books on power plant chemistry and air pollution control. He serves on the Editorial Advisory Board of Water Technology, and is a member of the ACS, AIChE, AIST, ASME, AWT, NACE (now AMPP), and the Electric Utility Chemistry Workshop planning committee. He may be reached at [email protected].

About the Author

Brad Buecker

Brad Buecker currently serves as Senior Technical Consultant with SAMCO Technologies. He is also the owner of Buecker & Associates, LLC, which provides independent technical writing/marketing services. Buecker has many years of experience in or supporting the power industry, much of it in steam generation chemistry, water treatment, air quality control and results engineering positions with City Water, Light & Power (Springfield, Illinois) and Kansas City Power & Light Company's (now Evergy) La Cygne, Kansas, station. Additionally, his background includes 11 years with two engineering firms, Burns & McDonnell and Kiewit, and he spent two years as acting water/wastewater supervisor at a chemical plant. Buecker has a B.S. in chemistry from Iowa State University with additional course work in fluid mechanics, energy and materials balances, and advanced inorganic chemistry. He has authored or co-authored over 300 articles for various technical trade magazines, and he has written three books on power plant chemistry and air pollution control. He is a member of the ACS, AIChE, AIST, ASME, AWT, CTI, and he is active with Power-Gen International, the Electric Utility & Cogeneration Chemistry Workshop, and the International Water Conference. He can be reached at [email protected] and [email protected].