A combination of factors in recent years has led to increased attention to water management in the oil and gas industry, and solutions for produced water handling are explored to address these challenges. In particular, oil and gas companies face limited water resources in certain areas: development of water-intensive technologies to better exploit unconventional plays; excessive transportation and/or disposal costs for water; a changing regulatory environment; and a public push for sustainability and conservation relating to water as an important resource.

One of the more difficult water challenges the oil and gas industry encounters is that produced and flowback water streams must often be treated prior to disposal, reinjection or reuse. Because the capital and operating costs associated with most treatment systems can be high, the need for economical management of produced and flowback water is especially critical. High-performance filtration and separation systems for produced and flowback water streams are effective solutions for lower operating and capital costs and for adding value.

Some of the issues that both onshore and offshore oil and gas facility owners and operators are facing include, but are not limited to:

- Plugging of disposal wells and producing formations by solid particles and suspended oil droplets

- Plugging of lines, valves and orifices due to deposition of inorganic scales

- Exceeding discharged oil concentrations

- Growth of bacteria that plug lines and valves or result in the formation of harmful products

Conventional treatment schemes employ numerous technologies and still achieve inconsistent results. Continually changing inlet conditions often limit their effectiveness. Additionally, conventional systems often call for a heavy dose of chemicals, creating an ongoing economic and chemical management burden for the industry.

Two solutions for produced water and filtration are hydrocarbon recovery, used earlier in the produced water process, and particle-liquid separation for filtration around the produced water process.

Figure 1. Particle-liquid filtration skidded rental vessels

Image Courtesy Of Pentair

Hydrocarbon recovery for produced water handling

Effective hydrocarbon recovery and solids removal from produced water streams is critical; therefore, end users need and expect stable, reliable operations and optimal performance while also addressing the health and safety of surrounding environment. Some hydrocarbon recovery technologies provide dramatically improved solids control and hydrocarbon recovery, including the ability to remove solids as fine as a half micron with efficiencies up to 99.98 percent.

Some users employing hydrocarbon recovery produced water systems have experienced operational, environmental and economic benefits that include:

- Operational flexibility

- Reduction of lost energy

- Savings on chemical additives

- Lower maintenance costs associated with fouling

- Elimination of excursions

Modern hydrocarbon recovery systems have proven more effective than conventional solutions for a host of reasons. Most process water systems experience either periodic or continuous hydrocarbon and/or solids upsets that lead to diminished capacity, loss of valuable product, fouling of heat transfer surfaces and equipment, and – in extreme cases – shut down due to environmental emissions. Such challenges are alleviated when employing hydrocarbon recovery produced water systems.

Particle-liquid filtration for produced water handling

A high-performance separator with filter elements used for particle/liquid filtration are available as a self-contained skid or a stand-alone vessel. Compared with conventional cartridge filters, a high-performance separator with filter elements lowers operating costs and reduces disposal costs. Historically, many produced water filters have been undersized, leading to high change-out frequency and high operating costs. Utilizing an appropriate design basis is critical to achieving both desired filtration effectiveness, as well as cost-effective produced water operation.

The major advantage of an installation of this sort is its simplicity, as it has only two parts – the coreless element and the reusable core. The reusable core is semipermanently installed into the existing filter vessel without the need for special tools. After installation of the cores, the open end of the cartridge slides down over the length of the core and engages a positive sealing O-ring to integrally seal the filter and core together. The reusable cores have standard collapse ratings of 75 PSI or 150 PSI, depending on the series and material of construction. Higher collapse ratings are available upon request, and systems can support a range of media types and micron ratings to match requirements of the application.

Removing contaminants for Wyoming gas producer

When a gas producer in Wyoming experienced problems with deposits and corrosion in the company’s separators and in the piping within its liquids gathering facility, Pentair provided two ProcessOR particle rental skids as a possible solution for removing particulate contaminants in produced water and condensate.

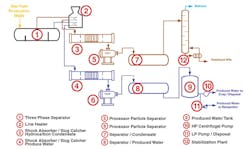

To mitigate the deposition of solids in the disposal well system, Pentair rental particle filters were implemented on the produced water flow. Likewise, to prevent deposition of solids and related under deposit corrosion in the condensate stabilizer, the producer installed Pentair’s filtration equipment on the condensate feed as well. Often condensate systems experience poor water separation prior to the stabilizer column, which can result in column flooding from entrained water and high corrosion and fouling from entrained salts. In cases where water carryover to the stabilizer is a concern, filtration can be coupled with Pentair’s LIQUISEP technology to remove water as well. The process flow diagram in Figure 2 shows the liquid processing equipment installed at the liquids gathering facility for the customer to evaluate. As the diagram indicates (Figure 1), the liquids were separated into condensate and hydrocarbon in a three-phase separator. The water removed from the gas – the produced water – was disposed of in injection wells and evaporation ponds nearby. The condensate was fed to a stabilizer unit where it was separated into usable products for transport by pipeline.

After using the rental skids during the evaluation, the customer was extremely satisfied with the performance. The customer ordered two additional skids for use in an identical liquid gathering facility and in the construction of a new facility in Utah.

Carl Hahn, Ph.D., is the senior global sales director for Pentair Separations. He joined the company in 2007 as part of Pentair’s acquisition of Porous Media Corporation. Dr. Hahn has an extensive background in process optimization through advanced separations applied to oil and gas production, petroleum refining, petrochemical and specialty chemical manufacturing. He holds multiple U.S. patents. He graduated with a bachelor’s degree in chemistry from the University of Michigan and earned a Ph.D. in chemistry from Princeton University. While at Princeton, Dr. Hahn was also enrolled in the Science, Technology and Environmental Public Policy Program at the Woodrow Wilson School of Public and International Affairs.