Peracetic acid — otherwise known as peroxyacetic acid or PAA — is a powerful disinfecting and sanitizing agent that is increasing in popularity as a wastewater treatment chemistry. PAA is federally approved for use in wastewater disinfection and is currently permitted in 18 states, with six additional states in the process of gaining approval. PAA is a highly reactive, efficient chemistry that provides significant benefits to wastewater treatment plant operations.

PAA exists as a stabilized equilibrium reaction of hydrogen peroxide, acetic acid and water. This equilibrium allows PAA to be an ideal disinfecting agent in water and wastewater as it is non-bioaccumulating with rapid environmental breakdown into innocuous byproducts. However, due to its chemical makeup, PAA has also been the subject of several questions about increasing biological oxygen demand (BOD) in wastewater, especially when dosed at higher concentrations.

This article will explore the topic in detail and conclude that PAA contributes only minimal BOD increases to wastewater effluent and has no consequential impact in wastewater systems that do not already have BOD levels close to discharge consent limits.

About PAA for wastewater treatment

PAA has been used as an alternative to chlorine as a wastewater disinfectant since it received federal approval. A powerful oxidizer, PAA has several advantages over chlorine chemistries, including lower costs, lower chemical use, fewer process steps and no regulated disinfection byproducts.

PAA neutralizes bacteria, viruses, fungi and other bio contaminants that can impede wastewater treatment facilities from meeting sanitation standards and permit requirements. The oxidation potential of PAA is higher than other chemicals used in water and wastewater treatment — including chlorine alternatives — which enables it to provide a more rapid rate of disinfection. Despite this higher oxidative power and rapid environmental decay, PAA is stable enough to provide a final effluent half-life often exceeding two hours.

PAA is available in a variety of concentrations and is used in many different industrial applications such as: food and beverage, meat and poultry, and oil and gas markets. Most commonly in wastewater disinfection, 15% PAA solutions are used. However, other strengths like 12% and 22% are available.

PAA offers wastewater treatment operators:

- More powerful and higher oxidation potential than chlorine alternatives.

- Does not require a neutralizing agent to make water safe for discharge.

- Breaks down into water, hydrogen peroxide and acetic acid (vinegar).

- Can be used in conjunction with UV disinfection.

- Requires no risk management plan or operator certification for safe handling and storage.

PAA vs. chlorine

As more wastewater systems look for alternatives to chlorine products due to handling needs, environmental impact and changing regulations, PAA has emerged as a green “next generation” wastewater treatment option. Because of its simple organic structure and equilibrium stabilization, PAA decomposes to oxygen and water, unlike chlorine products, which require a powerful neutralizing agent as a last step in the process to remove residual chemistry.

Operators considering a switch from chlorine to PAA are attracted by several advantages:

- Much lower CAPEX costs compared to UV, ozone, or other alternatives.

- Most existing infrastructure (depending on composition) can be used with PAA, lowering conversion costs.

- Does not produce trihalomethanes (THMs) or other harmful or regulated byproducts.

According to WaterOperator.org, wastewater systems consider moving to peracetic acid for several reasons.

- Unlike chlorine alternatives, PAA decomposes into biodegradable residuals that can pass whole effluent toxicity tests without removal

- Residuals and subsequent byproducts are not toxic, mutagenic, or carcinogenic

- Bioaccumulation in aquatic organisms is highly unlikely

- Neither chlorinated compounds nor harmful disinfection by-products (DBPs) are produced with its use

As such, PAA is being utilized as the answer to tough DBP regulations. PAA can also disinfect over a wider pH range and is unaffected by nitrate and ammonia concentrations.

BOD in wastewater

According to the U.S. Geological Survey, determining how organic matter affects the concentration of dissolved oxygen is integral to water-quality management and environmental protection. BOD is a measure of the amount of dissolved oxygen that will be removed by bacteria in a receiving water stream when they start to feed on the nutrients introduced by the wastewater. More nutrients in the wastewater means more bacterial growth, which means less dissolved oxygen in the receiving stream, potentially impacting aquatic organisms such as plants and fish.

Left unchecked, introducing wastewater with high BOD levels can lead to large scale eutrophication such as algal blooms, which can have devastating effects on aquatic ecology.

To protect against these negative impacts, BOD wastewater levels are strictly regulated as part of discharge permits and routinely analyzed to ensure compliance. BOD levels can fluctuate for many reasons, including influent quality and volume, fertilizer runoffs, treatment capacity and digestor efficiency to name a few. Plants often see cycles in BOD levels that can be mapped to these and other factors.

To accommodate for these cycles and natural variations, wastewater treatment plants are designed to ensure there is BOD removal capacity to spare and few modern plants come close to their discharge permit limits.

BOD and PAA

The effectiveness of a peracetic acid disinfection system depends on the oxidant demand of the wastewater, the initial microbial loading and a combination of the concentration of PAA and the amount of time the microorganisms are exposed to the PAA, often referred to as the CT. Even with these variables, most facilities achieve disinfection success with less than 5 ppm (parts per million) with average dosing around 2 ppm.

Due to the PAA and acetic acid molecules being simple, carbon-based organic structures, they are themselves a food source for bacteria, contributing to the family of assimilable organic carbons (AOCs) that are present in all natural and wastewaters. Therefore, dosing a wastewater stream with PAA adds two kinds of AOCs to the water, increasing the BOD by providing additional nutrients for bacterial growth.

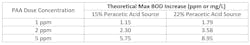

Theoretical maximum BOD increases for a 1, 2 and 5 ppm dose of peracetic acid are shown below for typical 15% and 22% PAA formulations, which differ due to the PAA ratios in each formula:

For many wastewater treatment plants, the theoretical maximum increases would not be sufficient to push BOD levels above permit limits. However, at higher concentrations it is understandable how an 8.95 ppm BOD increase could be a cause of concern.

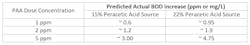

In practical application, measured BOD increases are often half of their theoretical maximum. This is because theoretical calculations do not account for:

- Hydrogen peroxide, which is present in both formulas and breaks down to form additional dissolved oxygen, counteracting BOD contribution.

- Oxidation of nutrient sources making them unavailable to bacteria, balancing the introduction of new nutrient sources from peracetic and acetic acid molecules.

A pilot PAA trial at a large treatment plant in Tennessee in 2015 showed that when using a 22% PAA source, actual BOD increases were only 52% of their predicted theoretical maximum.

Regulations on BOD levels vary from state to state. Extrapolating from real world trials, BOD increases from dosing PAA are operationally negligible in a vast majority of wastewater facilities. However, facilities with recurring high BOD that struggle to meet their existing permitted limits may not be suitable for a change to PAA, especially where higher doses may be required.

Takeaways

Field trials and real-world testing by Enviro Tech – a PAA manufacturer – show that the BOD increase in wastewater effluent due to the use of a PAA product for disinfection is significantly below theoretically predicted levels and is not likely to affect BOD regulatory compliance in all but a handful of facilities that already struggle with high BOD.

Wastewater treatment plant operators should not be concerned about PAA raising BOD in most situations, and PAA remains one of the best options for wastewater treatment based on high disinfection performance, eliminating byproduct formation, CAPEX/OPEX outlays and ease of installation.

Jacquelyn N. Wilson is technical sales Manager at Enviro Tech.

David Hird is associate director, research & development at Enviro Tech.