The Graver Trisep Oil Coalescer from Marmon Industrial Water is far from cutting edge — in fact, it is based on long-proven technology invented in the 1970s that has barely changed since. Using an oleophilic resin, the Trisep leverages the simple dynamics of water and oil to separate them efficiently and cleanly. While the technology is not new, emerging applications are bringing oil coalescers back into the spotlight. In a time when industrial wastewater regulations are increasing and oil recovery operations are expanding, this old technology is new again.

The problem of oil in water

From a process perspective, oil in water can inhibit performance and damage downstream equipment. For a wide range of equipment, keeping oil out of water is a requirement for protecting assets, maintaining process uptime and optimizing performance.

From an economic perspective, companies that value oil as an asset seek to recover as much oil from their processes as possible to preserve potential revenue. For plants that do not process oil, the potential for equipment damage and unplanned downtime represents a significant economic risk.

From a sustainability perspective, new and more frequent state and federal regulations are being passed to protect human health from the effects of polluted water. With increasing wastewater standards governed by the Safe Drinking Water Act, more industries are required to clean their wastewater before discharging, and regulations around the concentration of contaminants — including oil — continue to grow more stringent.

How oil coalescing technology works

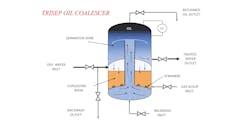

The Graver Trisep Oil Coalescer vessel is divided into upper and lower chambers by a steel plate. Oil water enters the lower chamber (coalescing zone) just below the plate and is pumped downward through a deep bed of oleophilic resin beads, where the finely emulsified oil coalesces. Large droplets (typically 0.5mm) of coalesced oil continually slip off the resin and rise with water to the upper chamber (separation zone) through a center channel. There, the oil droplets rise to the crown of the vessel and form a thick layer of oil, which is automatically decanted and recovered. Meanwhile, the deoiled water settles in the lower part of the upper chamber, where it exits the vessel.

The Trisep resin is self-regenerating, continuously, “dripping” oil droplets, ready to receive more oil. When influent contains suspended solids, the bulk of those solids will be filtered by the resin bed and the vessel will require occasional cleaning. This process is built in with a backwash procedure that reverses the flow, pushing water upward through the resin and forcing out accumulated contaminants through a backwash valve. The ability of the resin to act as a filter of suspended solids contributes to a higher quality of recovered oil that requires less finishing treatment.

The process is “upset-proof,” meaning that it will never back up or overflow, because the oil, governed by an automatic liquid level controller, will simply decant as it rises to the top.

The coalescing resin is rugged and stable, with permanent oleophilic properties. It works well in water with a pH range of 2 to 12 and in temperatures up to 250°F. Due to the simplicity and durability of the technology, this equipment lasts for decades.

Industries that most benefit from oil coalescing technology

Increasing regulations are driving industries of all types to explore better ways to remove oil from their wastewater before discharge. Oil coalescing filters can achieve very low PPM when cleaning process water, oily condensate, stormwater runoff and other industrial wastewater to meet increasingly strict regulations.

The oil and gas industry, especially refineries and fracking operations, are currently the most prolific users of this technology as an oil recovery technique with refinery process water, condensate and fracking-produced water. There are advantages regarding water recycling, too. Oil removal is key to being able to recycle both condensate and produced water, which offers significant economic, regulatory and sustainability benefits.

Emerging markets include power generation and food processing plants. Power generation facilities have massive and critical investment in increasingly sophisticated equipment and have shown a growing interest in keeping oil out of process water to protect their assets from oil-related damage The food processing industry — especially meat processing plants — is exploring oil coalescing technology to remove fats and oils from water to recover even more oil and grease, which is typically an additional revenue stream.

It is important to note that this technology is especially well-suited for situations where facilities want to reduce PPM to very low concentrations, as low as 1 PPM. While the technology can certainly accommodate oil water with concentrations of up to 1000 PPM, it would not be economically prudent to do so, as there are other less expensive methods that can handle removal down to 100-200 PPM.

Why oil coalescers are having a moment, again

Growing attention on sustainability, in both government regulation and the court of public opinion, is making oil coalescing an ideal choice for certain applications. As mentioned, increasing regulation of wastewater and rising environmental standards are one driver, as are the fines for violations. Also, as the process uses zero chemicals and very little energy, the technology gives a strong showing for companies with sustainability goals. The self-regenerating resin does not wear out, and with no moving parts the equipment requires very little maintenance, resulting in a product that is both economically advantageous and environmentally responsible.

The benefits to water recycling and oil recovery are also significant as companies seek to increase profits through waste reduction. For companies pursuing circularity, the Graver TriSep Oil Coalescer can play a key role.

How oil coalescing is a superior technique

The Graver Trisep Oil Coalescer can be used to deoil almost any oil-in-water emulsion or dispersion and competes most closely with air/gas flotation and activated carbon filtration. While these technologies do a good job of removing oil from water, neither is a good option when oil recovery is a goal — with fewer costs and less labor.

With air/gas flotation, the technology adequately separates water from oil and everything else in the water, so if cleaning process and produced water is the only objective, it is a good fit. But if oil recovery is desired, air/gas flotation, also known as dissolved air flotation (DAF), is not a good option because it does not separate the oil from other solids in the water and results in a waste stream that must be managed.

Activated carbon filters act as an oil sponge, with a limited capacity. The higher the oil concentration of the influent, the faster the carbon media must be replaced, which adds supply, downtime and labor costs. Since the oil is bound up in the carbon media filter, the oil cannot be recovered and is lost to waste. The spent carbon must then be hauled off for disposal, possibly as hazardous waste. The Graver Trisep Oil Coalescer eliminates all these costs and recovers the oil, with a minimal concession to water quality.

Other advantages include:

- High performance: Oil concentration can be reduced to as low as 1PPM.

- Clean and dry recovered oil: Oil recovery rate can be as high as 99%.

- Resistant to flow surges.

- Impossible to upset: Recovered oil decants from the vessel as quickly as it emerges from the separation tank.

- No treatment chemicals: Zero chemicals are used, which saves operating expenses and doesn’t degrade the environmental profile of the water effluent.

- Low maintenance: System has no moving parts, and the oleophilic resin is extremely long-lasting and self-regenerating.

- Labor non-intensive: The operation is fully automatic.

- Low operating expenses: No chemicals, no media replacement, low energy requirements, low maintenance and labor demands all add up to exceptionally low operating expenses.

Old tools can deliver new value

While we live in a world that values newness, older technologies can offer novel uses and solutions to new challenges. Change is a constant, and adapting can and should include consideration of the new value offered by old tools. Doing so offers a shortcut to technological innovation by looking to the genius of the past to solve the problems of today.

With over 30 years of experience in the water industry, Yen drives innovation and revenue growth for the industry through capital equipment, aftermarket parts and service solutions. Before his tenure at Marmon Industrial Water, he previously held roles as BASF and Siemens Water Technologies (now Evoqua). He has a B.S. Ch. E. from Rutgers University and an M.S. in management science from the University of Massachusetts, Lowell.