Water, Energy Conservation in the Pharmaceutical Industry

By Michael Costello

Water and energy are intertwined. Not that long ago, water and energy conservation contributed little moreThe pharmaceutical industry requires consistent, high-quality water for production and wastewater treatment.

Because of this increased focus on water and energy, companies are evaluating new technologies and integrated solutions to reduce water consumption and increase energy efficiency. These new technologies and solutions cannot, however, compromise the dependability and robustness demanded by the marketplace. There is perhaps no better example of the need for dependable water solutions and product safety than in the pharmaceutical industry.

For pharmaceutical applications, there are three main drivers that force the issues of utility conservation into product design: long-term lifecycle costs, regulatory requirements and conservation/corporate responsibility.

Operating cost reduction has become increasingly important for pharmaceuticals and virtually every other industry to allow companies to operate as efficiently as possible. Reducing the cost of ownership on a water system is an important aspect of system design. Exploring new methods to reduce the cost of treating water, wastewater discharge, and utility expenses challenges decades-old system designs. Many cost savings techniques can actually offer enhanced reliability and performance of conventional water systems, while lowering cost of ownership.

Achieving regulatory requirements on a water system design usually includes two distinct areas of responsibility in a pharmaceutical application: maintaining minimum water quality standards for discharge or reuse within the facility and meeting discharge volume from the facility. There are specific contaminant limits on the discharge of water into municipalities or other waste streams. Exceeding these limits can result in severe financial penalties or put a plant’s operation at risk. In particular, pharmaceutical manufacturers must operate within strict national and local regulatory limits.

Finally, conservation of natural resources and public perception of the pharmaceutical manufacturers is critical for the image of these companies. Companies can receive negative public perception and ratings from regulatory bodies as well as shareholders, if not operating at an optimal level. More and more, companies want to be recognized for the efficient use of natural resources and a gentle global footprint. In addition, companies experience increased scrutiny and pressure from various entities including the public, regarding concerns about pharmaceuticals in drinking water. So, ensuring tight management of water supply is a serious and critical point for pharmaceutical manufacturers—both in the manufacturing process and in product development.

Microbial Contamination

Water is used widely during the production of pharmaceutical products as a direct ingredient as well as indirect uses such as formulation, rinsing, sanitizing and cleaning. Most high quality makeup water systems used within pharmaceutical production have some element of recirculation inherent in the system design. When water is not needed, water systems typically go into a recirculating standby mode to control microbial proliferation within the water and on the wetted surfaces of the water system. This conventional approach has been used for decades and has been considered the best ‘in situ’ approach for controlling microbial contamination. Often, microbial contamination is the most difficult, and costly, aspect of the water system design. While chemical and organic impurities can usually be managed with little difficulty, proliferation of bacteria, viruses and other organisms can challenge even the best system designs.

Operating costs have become increasingly important for pharmaceutical and virtually every other industry.

In an effort to build robustness into the water systems of a pharmaceutical facility, many of these systems are built with a 2 x 100% redundancy approach. This ensures the water system is always available when needed. All water systems require periodic maintenance monitoring and adjustments, and a redundant water system approach allows one train to be available while the other train is being serviced or maintained. This redundant water train will continually recirculate while in the standby mode, and will consume water and electricity, and produce wastewater, nearly 100% of the time since it is by nature a standby or backup system.

Technology Developments

Recent technology developments for pharmaceutical water systems eliminate the need to continually recirculate water. The S3® system, a new technology provided by Siemens Water Technologies, uses a sanitize/start/stop approach rather than a recirculating water system design. A traditional water system constantly recirculates water, which consumes electricity for pumps, ultraviolet lights, instruments and other devices. Often the water must be heated or cooled to maintain adequate water temperature specifications. Additionally, certain unit processes such as reverse osmosis produce a waste stream during operation. A recirculating water system, even if it is not currently producing water for production, is producing waste that must be discharged or treated prior to discharge. These systems can consume valuable raw water, consume electrical and steam utilities and produce a wastewater stream even if the water system is not being used in the production process.

A sanitize/start/stop design eliminates most of this waste by shutting down the water system when not needed. While in the standby mode, the system will briefly turn on and receive periodic heat sanitization during extended periods of non-use. These sanitization periods are quick and relatively low temperature (typically 60°C) rather than the more typical 80 to 85°C. The brief but frequent sanitization periods are very effective at challenging microbial proliferation within a water system. When the pharmaceutical production requires water, the system performs a brief pulse sanitization just before water is sent to the manufacturing process. This ensures the water system is freshly sanitized for optimal water quality when it is needed. Standby or redundant trains can now sit relatively idle, receiving periodic pulse sanitizations to maintain water quality. Just like conventional water systems, the sanitize/start/stop design can be combined with chemical cleaning, chemical sanitization and conventional heat sanitization to address microbial contamination and biofilm formation within the water system.

The economic and water volume savings from the sanitize/start/stop approach can be dramatic, sometimes saving many millions of gallons of water per year. Large water systems, redundant trains, high raw water costs, high discharge water costs, and water discharge limitations can greatly impact the total savings. While the savings are greater on larger systems, even single-train, relatively small water systems with moderate water costs still result in rapid payback and significant savings.

For example, a healthcare products manufacturer in the Southeast USA is a major manufacturer of vision care products. Like most companies, they evaluated solutions for reducing water consumption and optimizing the production of their products. The company required a 150 gallon-per-minute treatment plant producing United States Pharmacopeia (USP) Purified Water quality water. System validation was unnecessary for this application.

The specifics for this example water system include:

- 150 GPM make-up water requirement

- Operation: 7 hours / day, 5 days / week, 350 days / year

- Feed water cost: $1.33 / 1000 gallons

- Wastewater discharge cost: $2.77 / 1000 gallons

- Electrical cost: $0.05 kWh

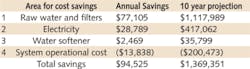

The following cost saving analysis includes an annual savings and 10-year projection that includes projected utility cost increases.

The total water system cost is less than the 10-year projected savings. The uniquely designed system can quickly pay for itself, typically with a payback period of six to 24 months after which the savings drops immediately to the bottom line of the manufacturer. But remember, the water system was required regardless of the savings.

Water Reuse

In an effort to reduce raw water consumption and wastewater production from its product manufacturing process, this same healthcare products manufacturer implemented a water reuse system. The primary driver was strict regulations on wastewater discharge from the facility. Failure to recover their wastewater and reuse it as feed water would have resulted in severe financial penalties, crippling the facility’s growth ability.

The wastewater includes a proprietary organic compound introduced during the manufacturing process. It is critical to remove this contaminant from the wastewater stream before it can be returned to the feed of the system for reuse. Additionally, while important to remove the organic compound, it was also desirable to selectively retain a proprietary inorganic compound in the wastewater stream. By removing the organic contaminant and leaving the selective inorganic compound intact, the wastewater stream could be returned to the feed system and used again, safely and efficiently.

Membrane solutions such as ultrafiltration, reverse osmosis, nano filtration, micro filtration and ceramic membranes were all considered as possible solutions for this process. Ultimately, nano filtration was selected because of its process characteristics in removing the organic contaminant while having minimal impact on the selective inorganic compound in the process.

The company was able to recover and reuse more than 52 million gallons a year of its waste stream. This equates to a savings of approximately $3.4 million over a 10-year period. These savings do not include the regulatory penalties avoided or the financial impact of the facility’s ability to grow in their respective marketplace.

Conclusion

Tight water management is a serious and critical point for pharmaceutical manufacturers—throughout the entire water operations. Unique designs and proven, innovative integrated operations can provide creative solutions that result in significant operational cost savings, greater regulatory compliance and ultimately reduced business risk. In addition, companies can implement “green” solutions, which support public and shareholder expectations with the benefit of greater marketplace competitiveness.

About the Author: Michael Costello leads the pharmaceutical business for Siemens Water Technologies globally. The company provides comprehensive water solutions in Pharmaceutical and Life Sciences including pretreatment, process water, wastewater, service and laboratory. Costello has over 25 years experience with Siemens, focused primarily on Pharmaceutical, Life Sciences and high purity applications. He may be contacted via e-mail at [email protected].