Avoiding Corrosion: Engineered Plastic Cooling Towers Earn an ‘A’ in Harsh Environments

by Ed Sullivan

Continual maintenance of a metal cooling tower can be catastrophically expensive if a failed or leaking cooling tower shuts down a process. It’s a tough world out there, especially in production areas that involve harsh chemicals or corrosive environmental conditions, including high moisture content of coastal air.

When it comes to handling heat generated in chemical and other process industries, taking a cooling tower offline due to pH problems, scale, leakage due to corrosion, or unplanned cleaning or repair can be disastrous, delaying production and shipments for days or even weeks. Maintenance costs for those often unnoticed-yet-critical towers, such as water treatment, filtration equipment and manual cleaning, can certainly add up. Mineral deposits or biofilm that coat or foul heat exchangers can cause far more expensive problems, including lowering process efficiencies or damaging production equipment.

Process interruptions and expensive maintenance of traditional metal clad cooling towers have increasingly led manufacturers and process industries down another path - the engineered plastic cooling tower.

Engineered with tough plastics such as high-density polyethylene (HDPE) to form a seamless, heavy-wall shell, today’s more advanced plastic cooling towers are virtually impervious to the harsh chemical, pH and environmental factors that are the bane of their metal-clad counterparts.

Yet, although they’ve been around for several years, the toughness and other performance attributes of engineered plastic cooling towers have gone unnoticed by many plant managers. That may be, at least in part, due to the fact that they perform so well their owners take them for granted. For chemical producer Allied Universal Corp., of Miami, FL, however, that isn’t quite the case.

“If a cooling tower goes down, we lose production, and it can adversely affect our delivery schedules,” said Jim Palmer, Allied Universal president. “We have a very corrosive and tough environment to have any type of equipment. And even though the cooling towers are not in direct contact with our products, they are exposed to corrosivity in the air.”

Allied Universal is the leading U.S. manufacturer of sodium hypochlorite (bleach), liquid sodium bisulfite, sulfuric acid and hydrochloric acid. With plants in Florida, Georgia, Mississippi, Arkansas and Arizona, the firm has been using engineered plastic cooling towers for approximately 15 years with highly reliable results.

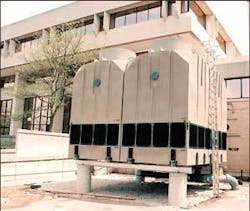

These have been largely the Paragon Series of factory assembled cooling towers manufactured by Delta Cooling Towers Inc. The series is a modular, induced draft design that includes a corrosion-proof HDPE shell and other design features that enable them to survive well in Allied Universal’s demanding manufacturing environments.

“We couldn’t make our products if we didn’t have consistent cooling towers,” Palmer said. “Because these chemicals are exothermic, they give off lots of heat. So, we run the product through one side of the heat exchanger, and flow cool water through the other side. The heat is taken out of the cooling water by the cooling tower, and given back to the environment before it recirculates. So, a continuous flow of cool water is essential.”

Palmer said his company decided to go with Delta because it’s one of the original developers of the engineered plastic cooling tower and offers good aftermarket support.

“I’ll give them an ‘A’ for quality and service,” Palmer said. “Their cooling towers are highly efficient and require much less service than the metal ones. In fact, there are some maintenance intervals that never happen because the plastic is impervious.”

Palmer said Allied Universal has some metal cooling towers that have been around for several years. In some cases, they’ve been welded so many times that the only repair possible is fiberglass patching.

“Fiberglass will last for awhile,” he said, “but after that, it’s time to get out your check book.”

The first plastic cooling towers became available in limited smaller sizes 35 years ago. Success of those early models gave rise to second, third and now a fourth generation of engineered plastic cooling towers much larger in capacity, lightweight and seamless. These towers don’t rust, chip, flake, peel or require paint or other protective coatings.

Employing advanced resins and molding techniques, today’s engineered plastic cooling towers are available in larger sizes and modular configurations for high-capacity applications (1,500-2,000 cooling tons). Designs such as the Paragon can be clustered for ease of installation and savings on footprint. They’re also lightweight, so less structural support is required, compared with many metal towers.

While the cost of electric power to drive cooling tower fans may seem incidental to process costs, they can also add up. Some manufacturers, such as Delta, use direct-drive motors to power cooling fans. With no pulleys, bearings and belts, these motors are more efficient and provide substantial savings in energy costs while also delivering more horsepower. Another benefit is fewer moving parts and maintenance items such as belts. When modular towers are incorporated into a cluster configuration, direct-drive tower motors can be shut off independent of others when supported processes aren’t operating.

Typically, molded polyethylene plastic water towers incur no problems from water treatments that may cause corrosion of metal parts or even a fungal attack of lumber on wooden cooling tower structures. Also, there’s no risk of water treatments causing removal of zinc from galvanized metal, which in some cases could result in the zinc migrating into the process - a potentially catastrophic problem.

Acknowledgment: The author would like to thank Delta Cooling Towers Inc., of Rockaway, NJ, a leader in packaged cooling systems, for its assistance on this article. Contact: 800-289.3358, [email protected] or www.deltacooling.com

About the Author: Ed Sullivan is a freelance writer based in Hermosa Beach, CA.