Water Reuse Model for Bottling Facilities

By Steven Pickle

Worldwide demand for water is constantly growing, and the scarcity of suitable water supplies afflicts populations and industries around the globe. Water-intensive sectors, such as the beverage industry, have the opportunity and the obligation to optimize their operations so as to increase water use efficiency and conserve water resources. This article describes a water reuse model that can help bottling plant operators determine what water sources can be reused and where they can be applied.

Optimizing water usage can be a complex issue for any bottling plant. But for a global enterprise like the Coca-Cola Co. (TCCC), any attempt to improve water use efficiency must accommodate myriad different installations, operating conditions, infrastructure limitations, and regulatory mandates. TCCC sought to develop a flexible tool that could help all of its local operators. To that end, a model was developed that would help improve water use efficiency throughout Coca-Cola's global network of bottling facilities. Once tested and refined, the model should be broadly applicable across the bottling industry.

The model incorporates bottling facility process and waste streams into a water use strategy-with and without varying levels of treatment and/or blending. While accommodating the broadest possible spectrum of operating conditions and constraints, the model provides a standardized approach to decision making that will aid in the cost-effective implementation of water use efficiency improvements.

Approach

The water reuse model is a spreadsheet-based method of optimizing water reuse decision making in bottling facilities. It provides a way to compare the relative benefits of direct reuse, and assesses various treatment options that would allow reuse.

A key metric used to measure water use efficiency is the water use ratio (WUR). The WUR is the ratio of the volume of water used in production to the volume of finished product. For example, a WUR of 3 indicates that 3 liters of water are required to produce each liter of product.

A key goal of the model was to incorporate the WUR into the decision-making process. As a user makes choices and assigns values to different parameters, the model calculates changes in the WUR, demonstrating the impact of different choices.

Bottling Facility

Concepts Water Balance

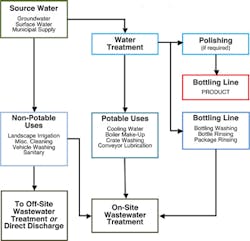

The model is designed to address water reuse at a typical bottling facility. This 'typical' facility includes potable water from a municipally treated ground water or surface water source; an on-site granular filter media water treatment plant; advanced water treatment (e.g., reverse osmosis); and an on-site wastewater treatment plant. Treated water is distributed for potable and non-potable uses, including the bottling line and other process demands.

The model begins by computing a water balance that identifies the many water streams that may be present at a bottling facility. The user simply enters the particulars for a given facility; applicable process streams are then incorporated into the water balance calculation, and non-applicable streams are automatically zeroed out.

Potable and Non-Potable Water Reuse

Water reuse was divided into potable and non-potable categories. Potable reuse entails treatment to reclaim high-quality water source streams suitable for human consumption. Non-potable reuse refers to returning reclaimed water to applications where there is no direct or indirect contact with the product or other potable streams.

Sources and Applications

Two broad categories of water streams are created through the water balance computation: sources and applications. The term "sources" refers to plant water streams that can be collected and used to replace a water demand at another location in the bottling plant. Applications refer to the locations that may be able to use reclaimed water. The model incorporates a variety of sources (such as membrane filtration concentrate, cooling water, or WWTP effluent) and applications (e.g., bottle warming, sanitary uses, or pump seal water).

Because of water quality concerns, only certain streams are feasible reuse sources. For example, the bottling line can only receive potable water from the water treatment or polishing plant. To accommodate such restrictions, the model matches the sources to the appropriate applications.

Possibilities for Reuse

Reuse without Treatment

Direct reuse involves the collection and use of either one source stream or a combination of sources for one or more applications-without any treatment or conditioning. This is possible when the collected source stream water quality meets or exceeds the target water quality of the application. If reuse of the selected source stream or streams is not possible due to water quality restrictions, direct reuse may be possible after blending with a higher quality source stream. Blending of a single source, or a combination of sources, is also evaluated by the model.

Reuse after Treatment

Treatment may be necessary to obtain an adequate water quality for a particular application or group of applications, or to increase the flexibility of how a source or collection of sources can be used. Removal of hardness or suspended solids, alkalinity reduction, and disinfection are examples of typical treatment requirements for reuse streams. The model attempts to balance the costs and potential benefits of a number of progressively more involved treatment categories.

Water Recycling

Another method of water reuse is to return used water to the headworks of an on-site water treatment plant. This is referred to as potable reuse by the model. Recycling is not possible for streams that would disrupt the operation of existing water treatment processes or have a negative impact on the water treatment facility's ability to meet its treatment goals. The model incorporates both water reuse and recycling into the WUR.

Model Approach

Water reuse strategies traditionally confine themselves to either 'big picture' guidance or individual facility-level planning. Unlike these divergent approaches, this model is focused enough to provide useful information, yet sufficiently general to be used by any bottling facility. Considering the variability of bottling conditions, infrastructure, and operator sophistication across TCCC's global operations, this flexibility is essential.

The model guides bottling facilities through a water reuse decision-making process. Based on the water reuse source streams and application points selected, the model recommends a water reuse strategy and demonstrates the impact of the user's decisions on the facility's overall water use efficiency, as reflected by the WUR.

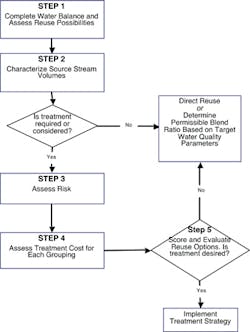

The model takes the user through a five-step cost-risk-benefit analysis between treatment options. Following creation of the water balance and the evaluation of water qualities and quantities in step 1 and step 2, the user can exit the treatment comparison and separately evaluate direct reuse possibilities-with and without blending. The user proceeds through steps 3, 4, and 5 if treatment still needs to be considered.

Model Sequence

The steps involved are described below:

Step 1a:

Creation of a facility water balance: A water balance identifies and quantifies all of the water streams in a facility. The model generates a second water balance that demonstrates how the user's water reuse decisions affect the individual and overall WUR.

Step 1b:

Identification of whether water reuse is feasible (based on water quality targets): The model next assesses where direct reuse is possible, and, if not, what treatment may be necessary.

Step 2a:

Characterization of source stream volumes: Using the source selections made in the previous step, the user allocates source water for reuse based on information identified in the water balance.

Step 2b:

Evaluation of direct reuse possibilities (including blending reuse source streams with treated water): After the source streams and volumes have been selected, the model determines which applications are suitable for the selected source streams. Custom water quality ranges can be input for each application, or default ranges can be used. At this point, the user can evaluate the impact of direct reuse on the facility WUR to determine whether to proceed to subsequent steps.

Step 2c:

Identification of treatment that would allow reuse: After the user determines which applications to include, the model compares all of the suitable applications. Source water is also allocated by the user to the available applications.

Step 3:

Evaluation of the risk associated with reuse choices: Each grouping of sources is assessed, using a scale of 1 (lowest) to 5 (highest) to indicate the risk posed to the bottling process. Users can modify the assigned numbers based on individual facility assessments, or if process changes are made to a particular bottling plant.

Step 4:

Evaluation of water reuse costs: Costs are assessed on a scale from 1 to 10 (from least to most expensive). As with the risk factors, default cost factors can be modified to reflect local considerations.

Step 5:

Evaluation of how water reuse decisions affect overall water use efficiency and the WUR: Reuse possibilities are evaluated in terms of volume, risk, and cost. Treatment options, including a no treatment option, are ranked by the model, and WUR implications are calculated.

Model Interface

The water reuse model was constructed atop a Microsoft Excel spreadsheet platform. The format readily allows modifications of input parameters reflecting local water quality conditions. The model also allows the user to conduct sensitivity analyses.

Information is loaded into protected worksheets that only permit the user to select and modify the appropriate cells. All other cells either use a constant value or are calculated by the model. Navigation aids are embedded throughout the worksheets. Decisions build on one another, and selections can be modified at will to see the impact on the cost-benefit analysis or WUR.

Additional Considerations

Blending

The model assesses blending using a mass balance worksheet that incorporates the quality of the reuse water, higher quality source water, and the target water quality. It allows the user to assess how much of a source stream, or combination of sources, could be used for a particular application.

Water Volume

Available water volumes and their impact on the WUR are important considerations. A low-volume reuse source may not make an appreciable impact on the WUR, even if it is a high-quality stream requiring little or no treatment. Conversely, collecting a reuse source that requires treatment may be worthwhile if the volume is sufficient.

Water Quality

Water quality within a bottling facility can be degraded by reusing water, which could lead to the concentration of total dissolved solids and other contaminants. The potential for changes in source water quality should be monitored and adjusted as necessary.

This is largely not a concern with the implementation of non-potable reuse, as the sources are generally separate from the applications. However, if water is collected and used in a way that creates a looped system, non-reused treated water must be periodically introduced to mitigate contaminant build-up.

Infrastructure

Due to variability among bottling facilities, the model cannot address specific infrastructure costs. Costs will increase as more sources are collected, and as the sophistication of treatment increases.

Water Use Optimization

Efficiency improvements in existing water uses should complement the introduction of a water reuse program. Small conservation measures and simple operational changes may actually be more effective and economical than water reuse.

Conclusion

To help reduce water use in multiple diverse bottling facilities, a model was developed that standardizes and automates water reuse decision making. The developed model provides a way to integrate and assess water reuse options. It offers guidance as to whether direct reuse is possible, and, if not, what type of treatment may be necessary. The model also assesses how blending can be applied to meet the water quality targets of the reuse applications. Ultimately, it demonstrates the impact of water reuse implementation on the overall WUR.

About the Author: Steven Pickle is an AECOM engineer specializing in water and wastewater treatment. He works in the firm's offices in Wakefield, Massachusetts.

Ed. Note: This article summarizes a paper presented at the WEFTEC convention held in Los Angeles, California, in November 2011. The original presentation-"An Innovative Water Reuse Model for Bottling Facilities in the Beverage Industry"-was written by AECOM's Steven Pickle, William Clunie, and Stephanie Gardner, along with and on behalf of Dr. Paul Bowen and The Coca-Cola Company. To obtain a copy of the original paper, please contact Steven Pickle at [email protected].