Embracing closed-loop technology for recycling and reuse

By Patricia Els

In recent years, efforts to reduce water consumption for high-demand industrial processes have produced effective sustainability initiatives with innovative technologies that reduce the environmental impact of many industrial processes. Advanced filtration technology and techniques that filter more complex contaminants without the use of chemicals in the treatment process are integral parts of this global movement.

Essential Resource in Aging Infrastructure

Water is the lowest cost utility and the most essential. Water usage for industrial purposes is only a piece of the global issue surrounding water demand. In fact, North Americans have the largest water footprint in the world at approximately 2,060 gallons per person per day, according to Nature.org.

Like crude oil, water prices have surged in the last 12 years, doubling or tripling in many parts of the U.S, according to a recent USA Today study of 100 municipalities. The ability to reuse wastewater using effective and environmentally-safe treatment methods has become a challenging issue for corporations and government officials at the state, local and federal levels.

Across our nation, aging infrastructure poses another challenge to recycling initiatives: The Environmental Protection Agency (EPA) estimates that to ensure water quality across the country, an overhaul of current infrastructures to meet regulatory standards would require $335 billion in capital expenditures for freshwater and $298 billion for wastewater over a 20-year period.

At the center of wastewater innovation is technology and industry and municipalities alike are adopting proven technology to improve treatment methods, increase volumes and meet water demands by recycling wastewater.

Non-Chemical Treatment for Wastewater Reuse

One such technology option is electrocoagulation, commonly called "EC." This technology is a closed-loop process that uses electricity to drive chemical reactions in a solution, suspension or emulsion to remove contaminants with 99.9-percent effectiveness.

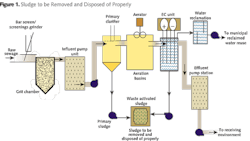

As wastewater contaminants pass by electro-rods, an electrical current is introduced into the wastewater stream. This electrical energy acts as the catalyst to initiate a chemical reaction, enabling contaminants to accept a positive and negative charge that causes tiny particles to bond together like miniature magnets. Contaminants are then automatically removed from the clear phase of water and transferred to a sludge dewatering system for easy management. Further, the oxidized metals can be removed from the sludge stream to be recycled as fertilizer, for example. Electrocoagulation will break oil emulsions and allow oil to float to the surface where it can be skimmed off with a vacuum and recovered if viable.

Chemical reactions occur within the wastewater, resulting in an uncontaminated product. The treatment process also overwhelms bacteria by pressure from excess electrons, causing the bacteria to be crushed. Likewise, small molds and algae are eliminated in the same manner. Materials such as sugar or salt that cannot be completely removed can be effectively treated with the addition of a polishing filter, such as reverse osmosis or membrane bioreactors (MBRs).

Used as stand-alone units or added to existing treatment facilities, EC units can treat up to an additional 15 million gallons per day of wastewater to then reuse for other purposes. This increases the capacity of traditional wastewater treatment facilities strained by increases in population and aging infrastructure.

Case Study: Municipal Sewage Treatment

Current sewage treatment systems require a large environmental footprint including the use of chemicals and large portions of land for effective treatment. The facilities require a network of settling and aeration tanks to manage the flow of water within one location. In addition, capacity is an ongoing problem. For low-lying areas and coastal communities, storm surges and high rainfall can quickly overwhelm treatment facilities with increased water volumes, causing a shutdown or otherwise compromising the plant. Oftentimes, beaches are ordered closed due to contamination from treatment plants.

Chemicals such as chlorine and bleach are typically introduced when the water processing is almost complete and ready for reuse. In terms of recycling, the water is then tested and discharged to reuse at golf courses, on construction sites and at compost facilities, for example. Discharges are typically diluted in rivers, lakes or lagoons. After further treatment, the discharged water can be used for irrigation or pipeed to underground outfalls to the sea.

Moreover, classes of unregulated organic compounds known as "emerging organic contaminants" have become a concern for water treatment engineers. These contaminants include pharmaceuticals and cosmetics, among others, that are being investigated as possible contaminants to aquatic and human life.

The use of electrocoagulation technology can improve the overall efficiency of a treatment facility and reduce volume burdens placed on highly-populated and rural areas. EC systems have processing rates of up to 15 million gallons per day. Used in tandem, EC technology can increase productivity and capacity at existing facilities, shorten the treatment process by reintroducing cleaner, treated wastewater later in the process or bypass the entire plant as a standalone treatment system.

Compared to traditional treatment methods, EC systems reduce the number of required settling ponds, eliminate odor problems and reduce sludge production, which lessens disposal costs.

In a pilot test study, we collected raw effluent water from a wastewater treatment plant. The use of polishing systems such as membrane technology or reverse osmosis was not used. Electrocoagulation was then performed with laboratory results producing a 100-percent reduction in bacteria, total suspended solids, phosphorus, and COD levels. In addition, greater than 75-percent reduction in CBOD, magnesium and iron was achieved.

Wastewater treated with electrocoagulation does not have a negative impact on any receiving environment. As such, the use of EC technology brings the treated water to a level where reuse without contaminating the environment is attainable.

Reuse Opportunities

Through the use of electrocoagulation, water can be reused in irrigation and agriculture instead of taking from aquifers and further depleting natural resources. The need for wastewater reuse options for urban, environmental, recreational, and agricultural usage will continue to be important for global sustainability efforts.

Recycled water can be used for the irrigation of public parks and residential landscapes, as well as fire protection and toilet flushing in commercial and industrial buildings. In addition to pond and sustaining stream flows, treated industrial wastewater can be used as process water for HVAC cooling and other non-potable needs. The combination of social acceptance and the adoption of new technology solutions by regulators will help continue meaningful progress towards reduced water consumption and the use of wastewater as a resource.

About the Author: Patricia Els is Chief Science Officer of Advanced Waste & Water Technology, Inc., a New York-based firm that specializes in the removal of chemical and liquid waste, water and waste treatment options and disposal services.